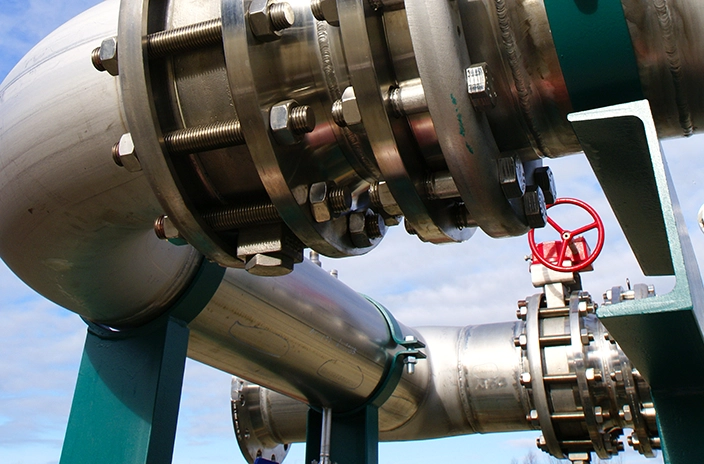

Protecting pipework and process equipment from CUI

Corrosion under insulation (CUI) is one of the major challenges facing equipment operators in the process industries today. As a result, many companies face significant lost revenue from downtime, maintenance and the replacement of corroded parts. During plant operation, hot pipework and equipment can be exposed to extremely high temperatures and temperature fluctuations. This causes micro-cracking in the anti-corrosive coating, which can cause corrosion beneath the insulation.

Learn how one polysilicon plant in China used our Versiline CUI 56990 coating to reduce downtime and maintenance costs.

The challenge

Much of the plant’s pipework and equipment is exposed to high temperatures, making it prone to corrosion under insulation. Conventional anti-corrosive solutions are often not able to protect equipment in these conditions, so the engineering and construction firm wanted an alternative but reliable and proven coating solution.

The solution

Combatting CUI at a Polysilicon Plant in China

The customer chose our Versiline CUI 56990 coating to protect the pipework, equipment and other hot surfaces at the plant. Versiline CUI 56990 can resist temperatures up to 650°C/1202°F, thermal shock and cycling in dry or wet service conditions. Importantly, thanks to its unique fibre-reinforced resin formula, it is extremely resistant to micro-cracking and subsequent corrosion, even in fluctuating temperatures.

At a glance

- Coating system: Versiline CUI 56990

- Application: Air spray

Dive deeper

Featured product brands

Our Cases

How we’ve helped our customers

Rapid cure lining ensures fast return to service at US refinery

Hempaline provides long lasting protection to crude storage tank, minimising future maintenance and repainting costs

Hempel solution trusted for valve coating

Hempel’s CUI and high heat solution is specified to provide corrosion protection across various temperature categories.

Quality matches speed as Koole meets tank project deadline

Persy Steel Protection partners Hempel to coat six tanks for Koole in a record-breaking five months