Unmatched performance in challenging environments

As we deepen our understanding of CUI and High Heat challenges and its impact, Hempel stays ahead of the curve in developing cutting-edge solutions tailored for insulated and non-insulated equipment in severely corrosive environments found in the oil and gas, chemical processing, and thermal power generation industries. From extensive testing to real-world applications, our commitment to excellence has proved true over the decades- providing real value for our customers and all stakeholders.

Our promise

Proven solutions for CUI and High Heat protection

Exceptional long-term performance

Hempel's CUI and high heat coatings are tested to the highest standards and provide unmatched protection against corrosion, extending asset lifespan and minimizing downtime, resulting in significant cost savings in insulated environments.

Advanced technology for improved maintenance

Our commitment to innovation has led to the development of cutting-edge CUI and High Heat coatings that embody the latest technology and decades of industry expertise, ensuring easy and fast application for better maintenance schedules.

Tailored solutions for specific needs

We understand the unique nature of each CUI challenge, offering a comprehensive range of customized CUI coatings tailored to address the specific requirements of different industries and applications. Our team of experts collaborate closely with customers so they can benefit from solutions that deliver optimal results.

Certifications

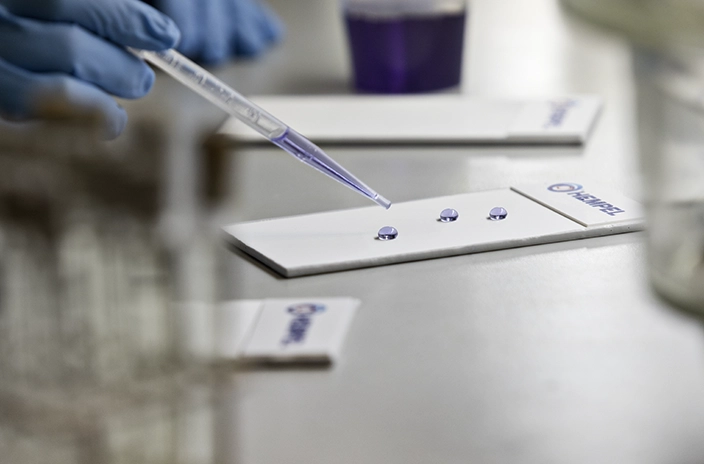

Quality coatings for a lifetime of protection

Developed at our CUI Centre of Excellence in Copenhagen, Denmark, our CUI and High Heat coatings are rigorously tested and certified to ensure they meet the highest quality and performance requirements for various applications. Our coating systems are up to date with standards such as ISO 9001, ISO 19277 : 2018, ISO 12944 and NORSOK M‑501, and our coatings meet with all relevant categories under NACE SP0198 : 2017.

-

ISO 19277: 2018Required for petroleum, petrochemical and natural gas industries, ISO 19277:2018 sets the qualification testing and acceptance criteria for protective coating systems under insulation.

-

ISO 12944ISO 12944 is the main international standard for corrosion of steel and paint, and we consider it one of the essential standards for selecting the most adequate coating system to protect your structures against corrosion including categories C5-H and CX.

-

Norsok M-501The NORSOK M-501 standard outlines surface preparation and protective coating requirements for offshore installations and their facilities. We produce coatings optimised to meet this standard, and we have a range of resources available to help you navigate it.

-

NACE SP0198 : 2017NACE SP0198 : 2017 provides a comprehensive guide to mitigating corrosion under insulation (CUI) in high-temperature industrial applications. It covers the latest technology and industry practices for designing, constructing, and maintaining systems to protect equipment and structures from CUI.

Explore our products

Hempaprime CUI 275

A high-performance alkylamine-cured epoxy to combat CUI, with short recoating and return to service intervals for higher productivity.

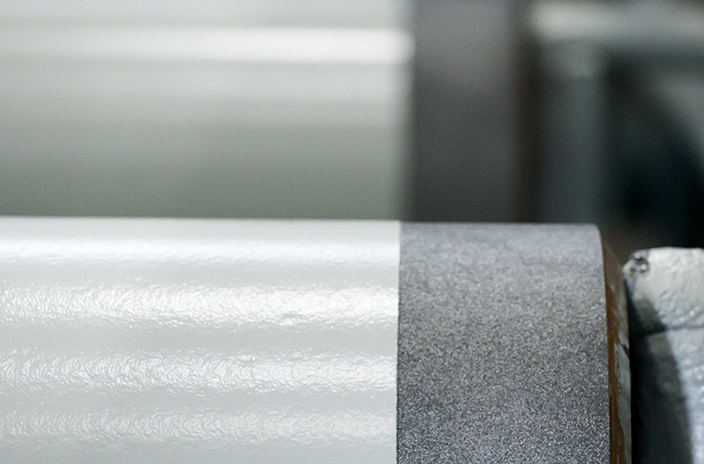

Versiline CUI 56990

A specialised fibre-reinforced copolymer coating for CUI and high-heat protection, resisting temperatures up to 650°C and containing excellent micro-cracking resistant properties for superior durability.

Case Stories | CUI & High Heat

How we’ve helped our customers

Case

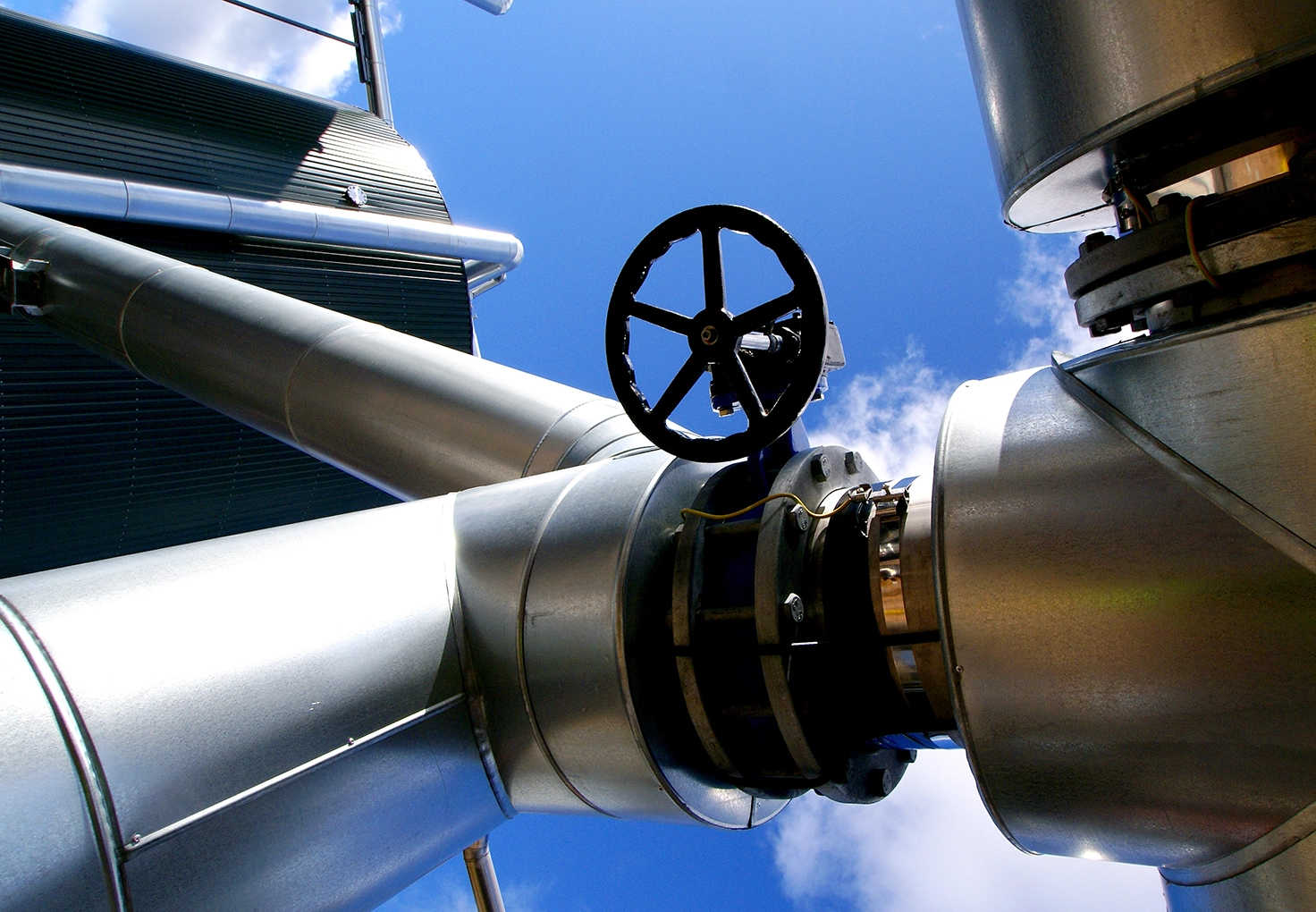

Protecting pipework and process equipment from CUI

Versiline CUI 56990 protects insulated pipework at polysilicon plant to reduce CUI risks and associated costs

Case

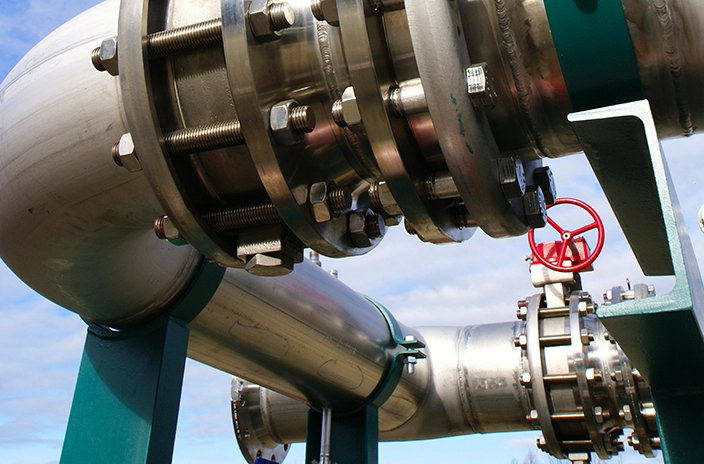

Hempel solution trusted for valve coating

Hempel’s CUI and high heat solution is specified to provide corrosion protection across various temperature categories.

Case

Long term protection and cost savings achieved during maintenance

Facility undergoes CUI maintenance without disruption to production schedule.