Long term protection and cost savings achieved during maintenance

Perhaps one of the toughest decisions in managing any industrial plant is knowing when to shut down production in order to carry out scheduled maintenance – finding the balance between market demands and seasonality, lost revenue and increased expenses, stopping today to be better tomorrow.

This is a challenge that has been successfully overcome at a geothermal facility in Europe, simply by carrying out maintenance, while keeping the plant in full production.

Geothermal power is a clean and renewable energy source. In some areas of the world, it provides a large proportion of the local population's energy supply. In 2011, geothermal overtook oil as the leading energy source there, thus preventing the emission of over 160,000 tonnes of CO2 per year and catering for more than 23 percent of the energy needs.

The trial

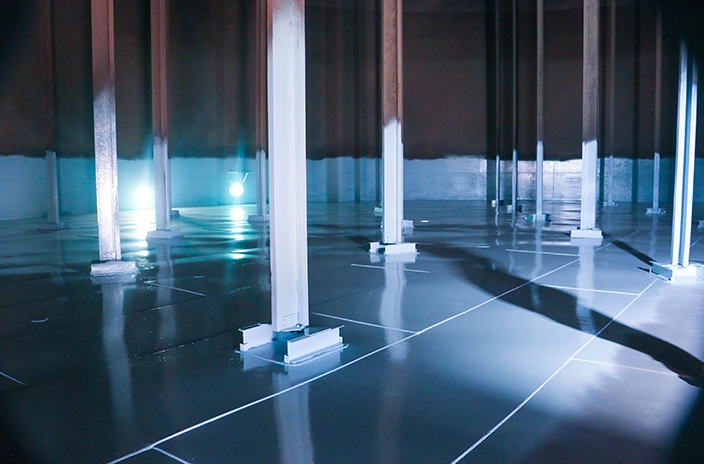

Facility undergoes CUI maintenance without disruption to production schedule.

Hempel has participated in a number of projects involving geothermal facilities. At one such maintenance project, our Versiline 56990 coating was being used to repair corrosion under insulation (CUI). In total, 1,700m2 of geofluid piping was being repaired. Such a project would normally require that the facility is shutdown during maintenance work. However, at this project the application company used a novel application technique to keep the plant operating. As a result, the client was not required to slow or halt production at any time in the process.

As is standard practice on any pipe coating renewal, the first stage was to strip the piping of its old insulated cladding to gain access to the steel pipe, which was then abrasive blasted to grade SA2½. Once the surface was suitably clean, it was coated with two 150 micron coats of Hempel’s Versiline 56990, our single component inorganic co-polymer coating designed specifically to protect against CUI, it was then insulated with new metal cladding.

The result

The project is a magnificent example of how Hempel's Versiline 56990 offers tremendous cost-saving benefits over conventional aluminium silicone coatings. In this case by offsetting the expense of scheduled maintenance by keeping production in full swing.

We would like to thank EDA Renovaveis and especially their manager, Eng. Carlos Bicudo, for their cooperation.

Naturally, Hempel experts are on hand to advise on how we can help you cut costs on maintenance.

Download the case story

Dive deeper

Featured product brands

Our Cases

How we’ve helped our customers

Verwater achieves rapid tank transformation without downtime

Leveraging Hempel’s expert support and Defend 630 lining system, Verwater completes tank building project for downstream client in Denmark

BPCL approves Hempaprime CUI 275 for superior CUI Protection

Hempaprime CUI 275 proves superior in safeguarding BPCL refinery assets against corrosion in thermal and insulated environments.

Storage Tank Protection with Hempaline Defend

Hempaline Defend 630 ensured fast turnaround for recoating a storage tank at Oldeval’s Medanito Pumping Station in Argentina, minimizing downtime and maximizing efficiency.