How can a new advanced water-repellent two-coat system extend maintenance intervals and reduce costs for offshore asset owners?

Due to the harsh marine environment and isolated location, offshore steel structures have long been difficult to maintain, leading to high maintenance costs for asset owners. In the oil & gas industry, three-coat anti-corrosive coating systems have traditionally been used for maintenance of offshore steel structures. However, these systems regularly show signs of early coating failure, primarily due to water ingress through the coating system, stress induced micro-cracking and/or mechanical damage. As a result, maintenance cycles are frequent, most asset owners struggle with a backlog of maintenance work, and maintenance costs – already high due to the difficulties of performing maintenance offshore – can become unsustainable.

Coatings manufacturer Hempel recently launched Hempatop Repel 800, the first volumetric water-repellent coating on the market. This article analyses the performance of this coating in a two-coat system with the activated zinc epoxy primer Avantguard 770. In extensive tests, the water-repellent two-coat system demonstrated significantly improved anti-corrosion performance compared to standard three-coat offshore maintenance systems, indicating that it has the potential to significantly extend maintenance intervals offshore and reduce maintenance costs for oil & gas offshore asset owners.

Properties influencing slip factor

Water-repellent coatings have long been a target for the coatings industry. By actively repelling water from the coated surface, a water-repellent coating can significantly improve corrosion protection, thereby extending maintenance cycles and reducing operational costs for offshore asset owners. Additionally, the water-repellent polyurethane topcoat analysed in this article ensures long-term protection for offshore assets when used as part of a two-coat system, which can be easily applied without special application equipment. There is a significant saving by moving to a two-coat system due to the reduced number of man-hours needed to apply the system compared to conventional three-coat systems, saving asset owners time and expense during asset maintenance and repair work.

Evaluating the performance of the water-repellent polyurethane topcoats

For comparative purposes, a standard polyurethane coating and the water-repellent polyurethane coating were tested through contact angle analysis and a salt spray test applied direct to metal.

Direct-to-metal salt spray test

In order to evaluate the corrosion resistance of the water-repellent polyurethane coating, it was exposed to a salt spray test according to ASTM B117-16 for a period of 768 hours and 1,440 hours. A standard polyurethane coating was also tested for comparative purposes.

Mild steel panels of rust grade A (ISO 8501-1) were abrasive blasted with iron grit. The surface of the panels had a roughness height (Rz) between 40μm and 55μm. The standard polyurethane coating and the water-repellent polyurethane coating were applied directly to the metal, with a dry film thickness of 120 microns.

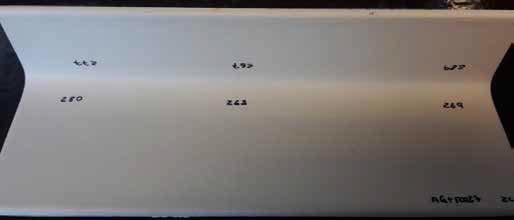

The results are shown in figures below. At 768 hours, the standard polyurethane coating showed a high degree of blistering. There were also tiny rust spots on the coating, although no flaking or cracking were observed. The water-repellent polyurethane coating showed no signs of rust, blistering, flaking or cracking. The creep line around the scribe area was considerably smaller on the water-repellent polyurethane. However, after 1,440 hours, tiny rust spots were observed under both coatings, indicating that moisture is able to penetrate the coatings after long exposure periods.

It is worth noting that salt spray tests of this type are not usually performed on single coatings due to the severity of the test. Instead, they are generally reserved for three-coat systems. In order to pass the test, a three-coat system of 280 microns must demonstrate less than 1mm rust creep around the scribe area after 1,440 hours of exposure. The water-repellent polyurethane coating saw rust creep of just 1.5mm after 1,440 hours, which is an extremely good performance for a single coating of 120 microns.

The standard polyurethane coating after 1440 hours of salt spray test.

The water-repellent polyurethane coating after 1440 hours of salt spray test.

Evaluating the performance of the water-repellent two-coat system

The anti-corrosive performance of the water-repellent two-coat system was evaluated through salt spray, cycling ageing resistance, blister box, thermal cycling crack resistance and flexibility tests.

The results show that the water-repellent two-coat system maintains its anti-corrosive properties for extended periods of exposure, making it a suitable for applications in aggressive corrosive environments, such as offshore oil & gas platforms.

The coating system used was:

- Activated zinc epoxy primer

- Water-repellent polyurethane topcoat

For the salt spray, cycling ageing resistance and blister box test, the dry film thickness of system was 280 microns (primer: 140 microns; topcoat: 140 microns). For the thermal cycling crack resistance and flexibility tests, the dry film thickness was increased to simulate over-application.

Extended salt spray tests

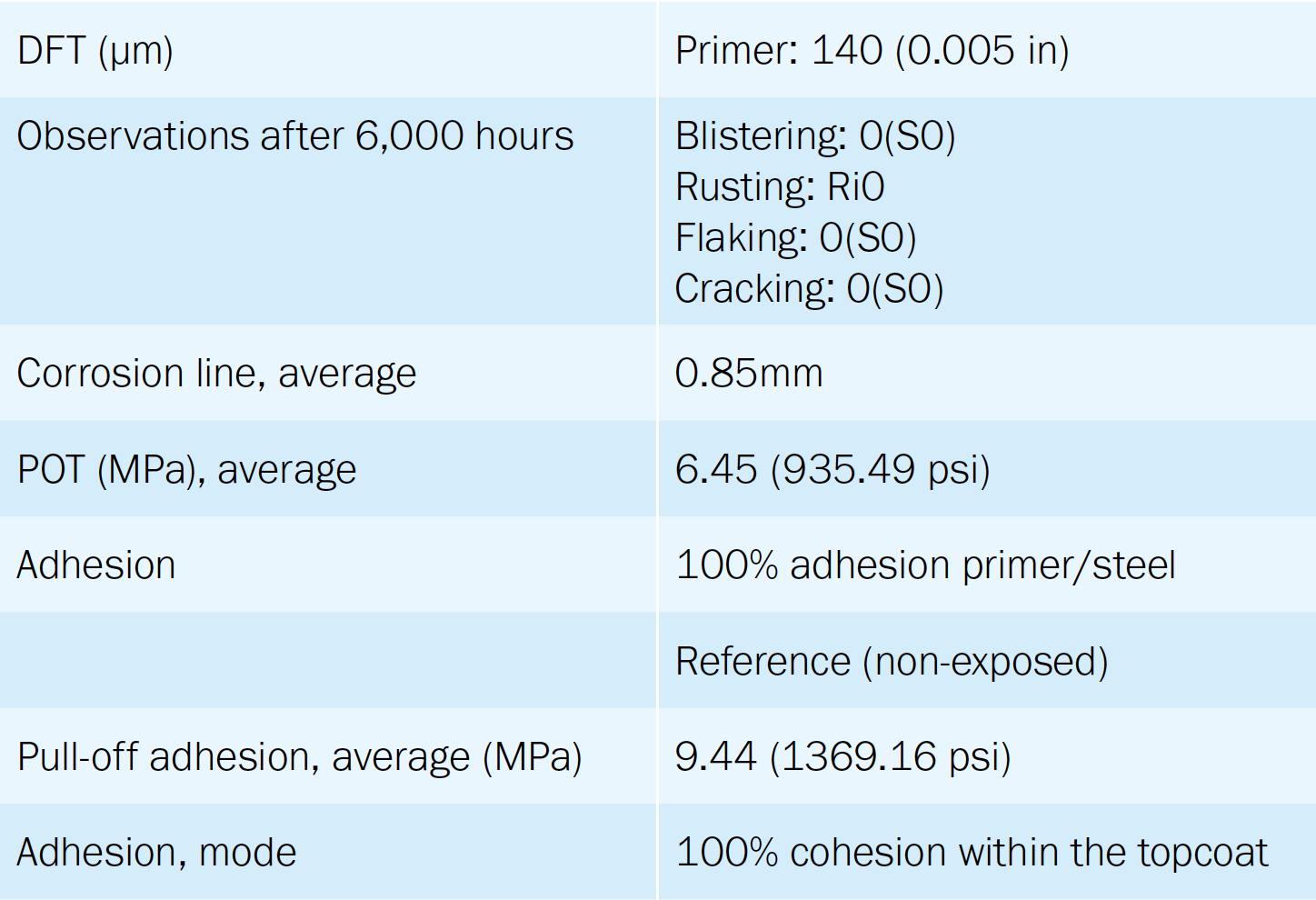

The water-repellent two-coat system was applied to metal panels. The panels were then exposed to salt spray tests for 6,000 hours, and measurements taken after 1,000, 3,000, 5,000 and 6,000 hours. It is worth nothing that this test goes well beyond a standard salt spray test of 1,440 hours.

The results are shown below. The panels were observed after different times of exposure in order to evaluate the degree of blistering, cracking, rusting and/or flaking. No visible defects were observed after the exposure times. After 6,000 hours of exposure, the corrosion line was less than 1mm, which is quite remarkable taking into consideration the extensive period time of exposure. The adhesion retention was 68% and the final adhesion is acceptable because it is greater than 5Mpa.

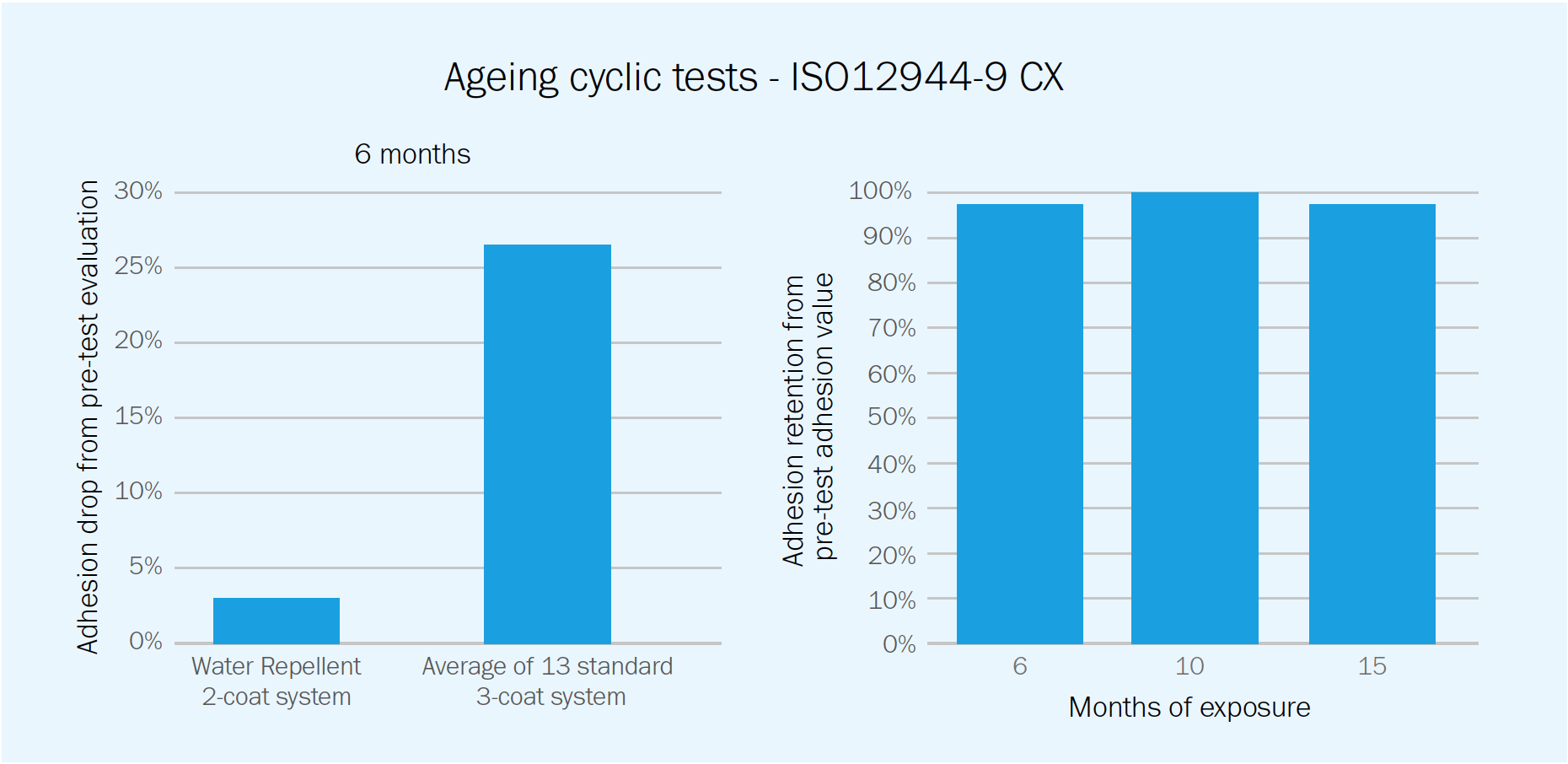

Ageing cycling resistance test

An aging cycling resistance test was performed according to the test methods in ISO 12944:2018 Part 9 for CX corrosivity. After the established 4,200 hours, no blistering, cracking, flaking, rust or any other visible defects were observed on the samples and the panels met the test requirements for this environment. Extended testing was also performed following the described method. Up to 7,200 and 10,080 hours, no blistering, cracking, flaking, rust or any other visible defects were observed on the samples.

As expected, the corrosion line increased with the time of exposure; however, rust creep slowed over time and the adhesion properties were not affected. In this test, a standard three-coat system would expect to see adhesion loss of 30-45%. The water-repellent two-coat system vastly outperformed this average; the adhesion properties of the panels maintained approximately 95% of their pre-test values.

Blister box test

A blister box test was performed according to ISO 6270. The water-repellent two-coat system was exposed to the blister box test for 7,200 hours – 10 times the usual test duration. After this period, the panels showed no signs of blistering, rusting, flaking or cracking. The panels showed a decrease of approximately 35% on the POT values when compared to the reference, but these are still regarded as acceptable (above 6 MPa).

Thermal cycling crack resistance

A thermal cycling crack resistance test was conducted under the same conditions as NACE standard TM0404- 2004, Section 9, but using L-shape panels instead of C-shaped profiles. The panels were post-cured at 60°C for one week and then subjected to upper and lower temperatures of 60°C to -30°C within a two-hour period for three weeks. At the end of the test period, the coatings were examined for cracking under a microscope, particularly at the corners where over application is normally observed. Neither prototype showed cracks or other defects.

As applicators can have a tendency to over-apply, especially in the corners, the dry film thicknesses of the coating system for this test was 500 microns. This is 2.5 times above the recommended dry film thickness of the water-repellent coating – and the performance indicates that the coating system will still perform extremely well, even if over-applied.

Representative picture of the water-repellent two-coat system following the thermal cycling crack resistance test. The system has a dry film thickness of 500 microns – 2.5 times the recommended dry film thickness of the system – but still shows no signs of cracks or other defects.

Flexibility tests

One side of the steel panels was coated and cured for two weeks. Afterwards, the test specimens were postcured at 60°C for one week and the respective flexure strain was measured using a fixed-radii mandrel bending machine. The panels were bent over the mandrel with the smallest radius available. No cracks were observed in the coating systems.

The test demonstrates the coating system has a flexural strain of 7%. This is a significant improvement compared to a standard polyurethane coating, which usually has a flexural strain of 1-3%, and shows that the coating is unlikely to crack under pressure or after movement in the steel. This is a very important consideration for coatings used on offshore oil & gas structures, which are often exposed to high temperature fluctuations and movement within the steel.

Summary

Coating maintenance and repair can be extremely time-consuming and costly for offshore asset owners. The isolated location of offshore assets makes maintenance work difficult, while standard repair costs are often swelled by travel and accommodation expenses for maintenance crew. Any coating system that extends maintenance intervals will have a significant benefit for asset owners, as it will reduce the frequency of maintenance visits and associated operational costs. As demonstrated here, a two-coat system consisting of a volumetric water-repellent topcoat and with an activated zinc epoxy primer system has the ability to do just that.

In addition, the system discussed in this paper requires fewer coats than traditional three-coat systems. This makes the system faster to apply – the entire system can be applied in a single day – which can significantly reduce maintenance and accommodation expenses for asset owners.

-

Notes

The authors are:

David Morton - Chief Scientist

Doug Mittlesteadt - Head of Energy GKAs and Oriol Osso, Group Product Management