A smarter path to resilient, low-carbon infrastructure

Lifecycle thinking turns protection into value

Preserving steel assets is one of construction’s smartest climate and business moves

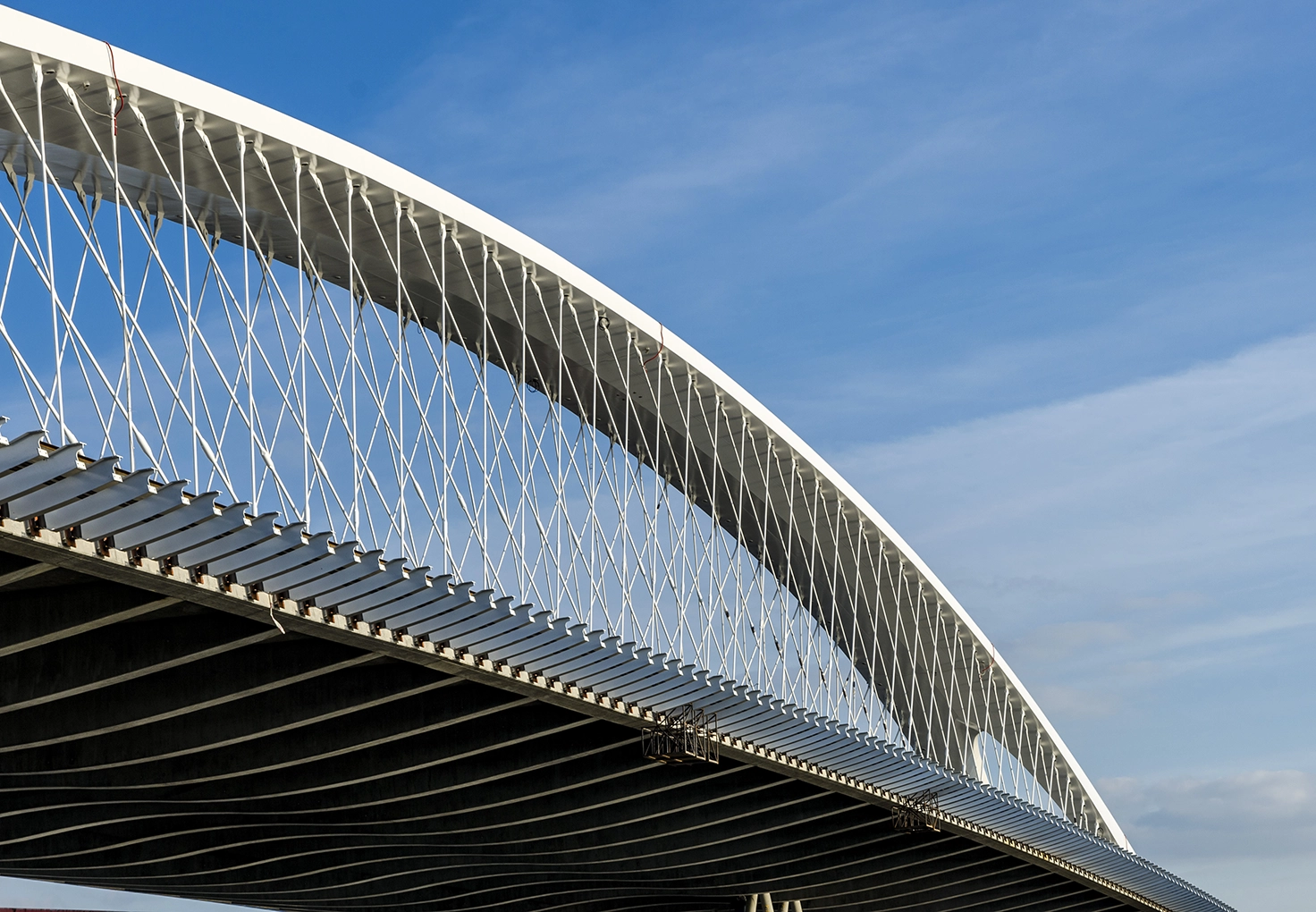

Steel is the backbone of modern infrastructure - bridges, ports, airports, buildings etc. But left unprotected, it corrodes. Oxygen, moisture and pollution trigger rust that weakens structures and forces costly, carbon-intensive replacements. The result: more emissions, higher maintenance costs and operational disruption.

For asset owners, engineers and operators, the real question isn’t which coating to choose; it’s how to protect the value and safety of what we build. Asset preservation isn’t about paint; it’s about performance.

Every bridge, tower and structural steel we save from premature failure is a climate action story in itselfMonica Li Aviram, Director, Solution Management - Infrastructure

The scale of the problem - and the opportunity

Steel production accounts for roughly 2.8 gigatonnes of CO₂ annually which equals about 7 - 9% of energy-related emissions. A significant share of that steel is simply replacing what’s been lost to corrosion - some studies suggest as much as a third.

Economically, corrosion eats away 3 - 4% of global GDP annually. That’s trillions in lost value, and much of it preventable.

Every tonne of steel we don’t have to remake through better protection saves both carbon and capital. Longer asset life means fewer shutdowns, lower total cost of ownership and a smaller environmental footprint - outcomes that investors, insurers, regulators and the general public now expect.

Shifting focus from “coating” to lifecycle performance

Coatings are just one part of a broader preservation strategy. What matters is predictable, measurable performance - bridges that last decades longer, industrial plants that run without unplanned downtime and assets that maintain value.

That requires:

- Lifecycle-based specifications – evaluate total cost and carbon, not lowest bid.

- Designing for access and inspection – easier maintenance equals lower long-term cost.

- Evidence-based asset management – use data to target interventions where they matter most.

Innovation that extends life and reduces impact

Advances in coating technology and surface preparation help owners extend service life while cutting environmental impact. The real value lies not in the chemistry itself, but in what it delivers: longer protection intervals, fewer interventions and reduced embodied carbon.

“Protecting assets is protecting value - for our balance sheets, for our communities and for the planet,“ Monica explains.The path forward

Preserving steel assets is one of the most practical ways the construction industry can cut emissions, lower costs and ensure safer, longer-lasting infrastructure.

- For owners, it means reduced lifecycle costs.

- For architects and engineers, it means design integrity that endures.

- For society, it means infrastructure that serves generations to come.

By treating corrosion protection as a strategic investment rather than a maintenance line item, we can create assets that stand the test of time - economically and environmentally. After all, the most sustainable structure is the one that doesn’t need to be rebuilt. And smart protection is how we get there.Monica Li Aviram, Director, Solution Management - Infrastructure