Corrosion under insulation (CUI) costs the thermal power generation industry millions each year in downtime and repairs - and the problem is getting worse

With the rise of renewable power, some fossil-fuelled power plants are increasingly run intermittently, as much needed capacity for when renewable energy is not enough. This repeated intermittent use leads to heating and cooling of equipment, which means the plants more often pass through the 60-150°C (175°F) temperature range, the danger area for corrosion under insulation.

The traditional coatings used in the thermal power generation industry are not designed to cope with these conditions. But the oil & gas industry has long had to deal with similar conditions. If coatings proven in oil & gas applications were more widely used in the thermal power generation industry, it would allow the industry to more proactively address the issue of CUI.

What is CUI?

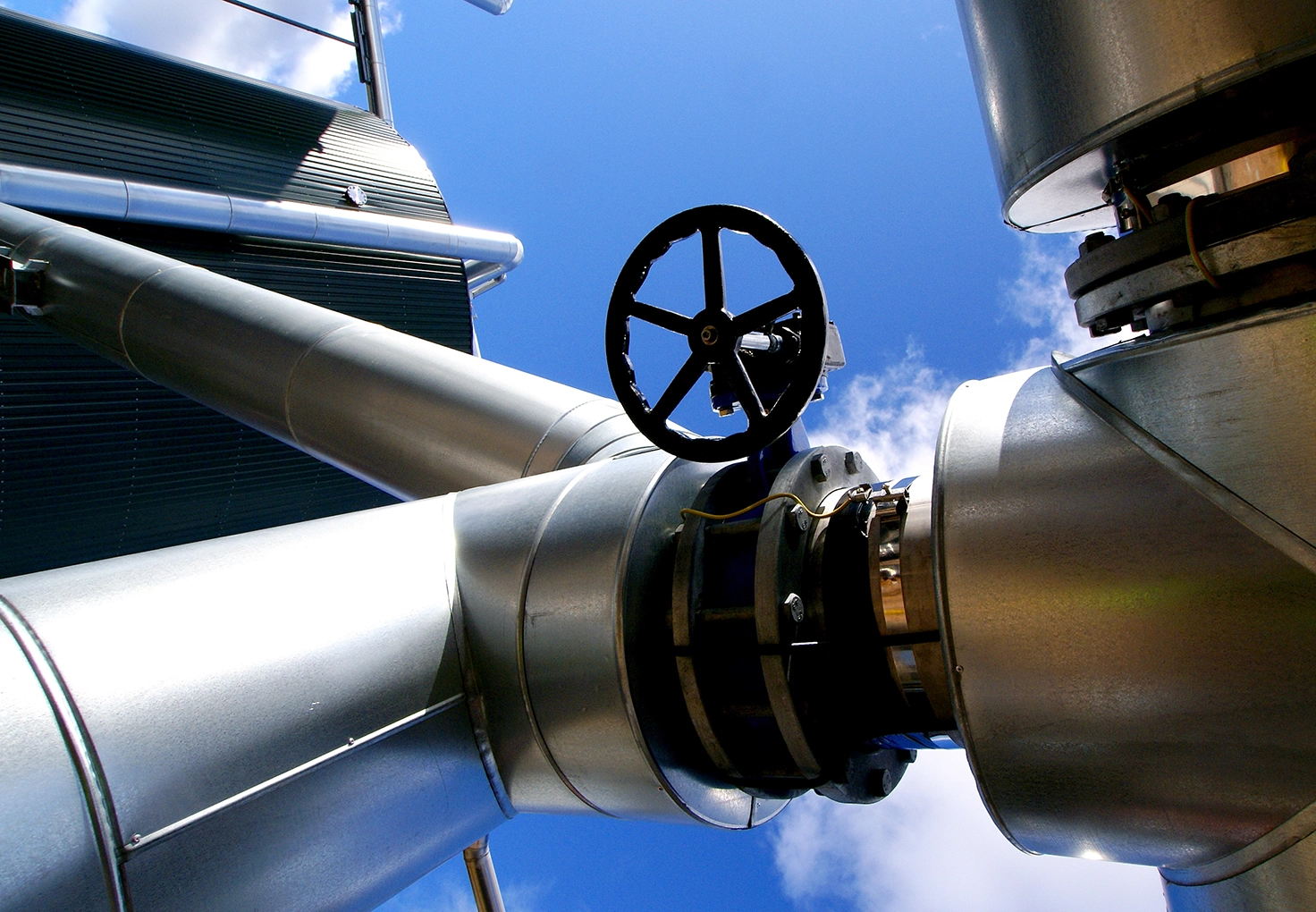

CUI occurs when moisture becomes trapped underneath insulation around pipework, ductwork, valves and other insulated equipment in the plant. This can be external water, which seeps through leaking and poorly maintained joins in the outer cladding, or condensation formed when the plant is heated and cooled. As it is beneath the insulation, the water does not have the opportunity to evaporate and so settles on the metal surfaces in the space between the insulation and the equipment substrate, subsequently leading to corrosion.

CUI caused by condensation is an increasing problem, as fossil-fuel-powered plants are spending more time cycling through the CUI temperature zone.

Why are traditional coatings not the answer?

Traditionally, the thermal power generation industry has used zinc silicates, often overcoated with zinc aluminium, on pipework, ductwork, valves and other insulated equipment. While these coatings perform very well at extremely high temperatures, they are not designed to handle a wide temperature range. In addition, when zinc silicates without topcoats or with topcoats that have degraded are exposed to repeated cycling in warm wet areas, the zinc is consumed extremely rapidly and corrosion quickly occurs.

Previously, this has not been a problem as most plants have operated almost constantly, meaning constant high temperatures and little or no condensation. But, in the new energy climate, with the intermittent operation required by practices such as peak shaving, these coatings are no longer the ideal choice.

Currently, whilst there are many standards and guidance documents around combatting CUI, there are no international standards for testing a coating’s ability to operate in CUI conditions. As a result, many ‘ad-hoc’ test programmes have been devised, but often designed with the oil & gas and process industries specifically in mind, not necessarily thermal power. A standard is being developed – with a number of companies involved, including international coatings manufacturer Hempel – but there is already a solution at hand.

What we can learn from the oil & gas industry

The simple solution to CUI is to overcoat the zinc with other coatings to prevent it from coming into contact with the warm wet environment. However, this approach has limitations. The topcoat used must be able to resist the temperatures concerned, provide good barrier properties in all temperature ranges where moisture is present and must, of course, be thoroughly compatible with the zinc silicate.

A better solution is to use inert multi-polymeric matrix type materials, such as Hempel’s Versiline CUI 56990, which has been proven on multiple projects around the globe. These coatings contain a silicone backbone, they are applied in thicker films and have better barrier properties than thin-film aluminium silicones, which offer limited corrosion protection. As a result, they provide far better CUI resistance during the time that the plant is in the CUI temperature zone.

Inert multi-polymeric matrixes have other advantages. They have a high temperature resistance, beyond the 400°C of zinc silicates. They are also faster drying than silicone aluminium coatings, and so can reduce downtime during maintenance and increase productivity when applied from new.

The final advantage with inert multi-polymeric matrix type materials is simplicity. They were initially developed for the oil & gas industry, because oil & gas applications involve a very wide temperature range. Inert multi-polymeric matrixes can be specified for a number of temperature and performance categories, making them ideal for bulk items such as pipework and valves.

By introducing these coatings, the thermal power generation industry has a ready-made solution for the CUI challenge – one of the biggest causes of lost uptime and extra maintenance in the industry today.