Prepare for growth by optimizing your blade coating processes

Internal knowledge indicates that blade coating processes typically require 40–60% of the available factory floor space. Optimizing coating takt times and application processes can reveal significant factory output improvements.

Hempablade coating systems drive productivity while complying to the industry’s requirement for optimum protection during the full life-time of blades.

Improve your blade manufacturing productivity levels with Less

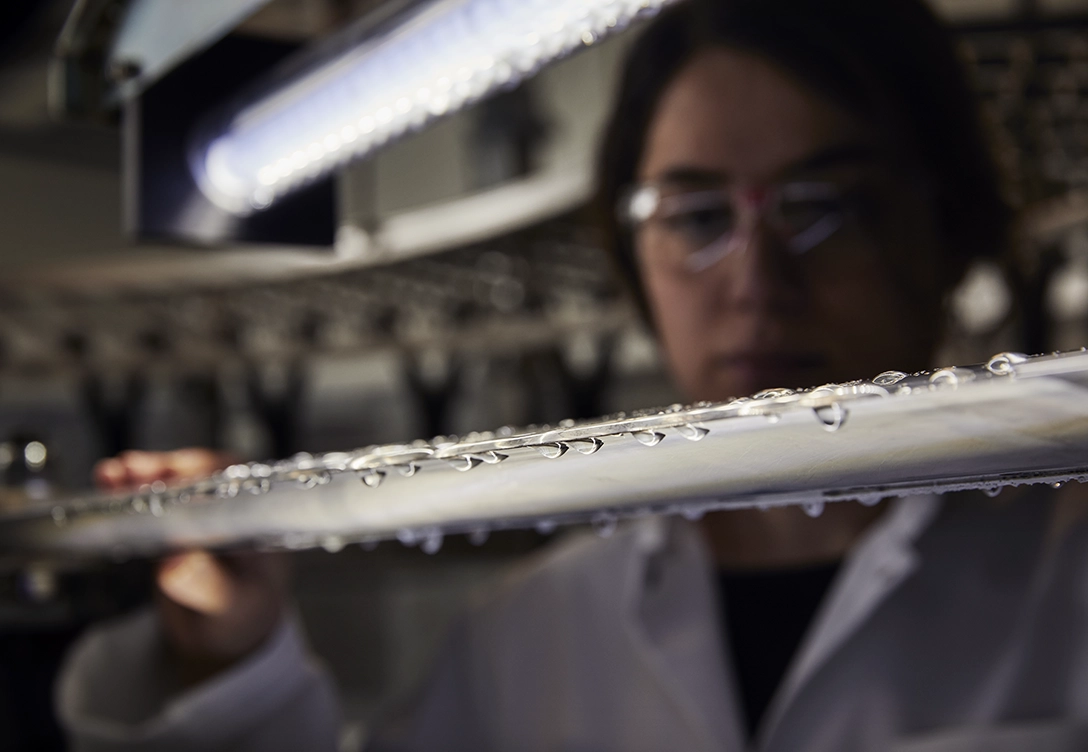

Straightforward, efficient application

Hempablade is more efficient to apply – it’s as simple as such. Our putty/filler system has proven to reduce application and sanding process costs by up to 40% and with fewer HSE concerns and faster throughput. Our topcoat system (waterborne or high-solid solvent borne) have fast curing profiles, and the application performance often lead to a 30% reduction in man-hours spend.

Reduce your warranty costs

Choosing Hempablade Edge LEP provides your blades with a strong leading edge protection. Early erosion on blades can cause significant challenges in your customer relation while unexpected maintenance costs and turbine availability claims can dilute profit. Leading edge protection is an investment and Hempablade Edge 171 and 172 has proven performance in both factory and maintenance environments.

The sustainable choice

The Hempablade coating system

-

Hempablade Putty 111A fast-curing, solvent-free and light-weight 2-component polyurethane putty that can be used to form edge profiles and fill defects on the surface of the wind turbine’s blade prior to finishing coatings or LEP. It offers a combination of a good mechanical properties, easy application and high-build capabilities.

-

Hempablade Pore 141A fast-curing, solvent-free, polyaspartic-based porefiller with excellent self properties that can be used to fill pinholes in substrates.

-

Hempablade Final 151A high performance, fast-curing, two-component waterborne polyurethane topcoat for wind turbine blades.

-

Hempablade Final 161Hempablade Final 161 is a high performance two-component polyaspartic based top coat for coating wind power plants in wind turbine blades.

-

Hempablade Edge 171A fast-curing top-layer designed to provide best-in-class erosion protection of the leading edge on wind turbine blades. Possibly the easiest application process for any LEP system available.

-

Hempablade Edge 172Hempablade Edge 172 is a fast cure high build top-layer designed to provide exceptional erosion protection of the leading edge on wind turbine rotor blades.

Benefit from our in-house Rain Erosion Test facility

Since 2019, we have our own in-house DNV GL RP-0171 compliant Rain Erosion Test facility, and we have put Hempablade Edge into several and exhaustive test sessions and assessments. This not only ensured the optimisation of its development and the LEP validation process, but it also means you can be sure it is proven to protect against rain erosion in the toughest conditions.

These rigorous tests culminated in a product that extends the intervals between scheduled maintenance, resulting in more turbine uptime and reduced operational costs.