Staying profitable in a challenging market

The wind industry faces demand to increase durability, which influences service providers and the entire value chain. That’s why it’s essential for you to get the most out of every maintenance job. But that’s not easy when you consider challenging site conditions, a limited maintenance season, and complicated application processes.

Focusing on blades is central to meeting the challenge as many older wind turbines have inadequate blade protection, and damaged or eroded blades cause poor aerodynamics. It is estimated that leading edge maintenance contributes to more than 50% of blade maintenance costs*. LEP protection is therefore key to increasing your AEP while ensuring benefits from longer service intervals and lower servicing costs.

*Source: Wood Mackenzie.

Let Hempablade Edge LEP boost your maintenance activities

Hempablade Edge 172 LEP coating is optimized for maintenance returning your turbine to operation as fast as possible.

Outstanding Leading Edge Protection

Speed matters

When the decision is made to stop a turbine for maintenance, coating systems and LEP need to limit time and costs involved. The Hempablade Edge 172 product is designed for a fast one-layer application process, but equally important fast curing allowing limited turbine down-time.

Simplify your work

One of the most important pieces of feedback we receive from our global customers is how easy the Hempablade Edge product is to work with in maintenance situations. Operators quickly learn to appreciate the 12-minute pot life, which allows them to ensure a strong application process and consistent coating quality.

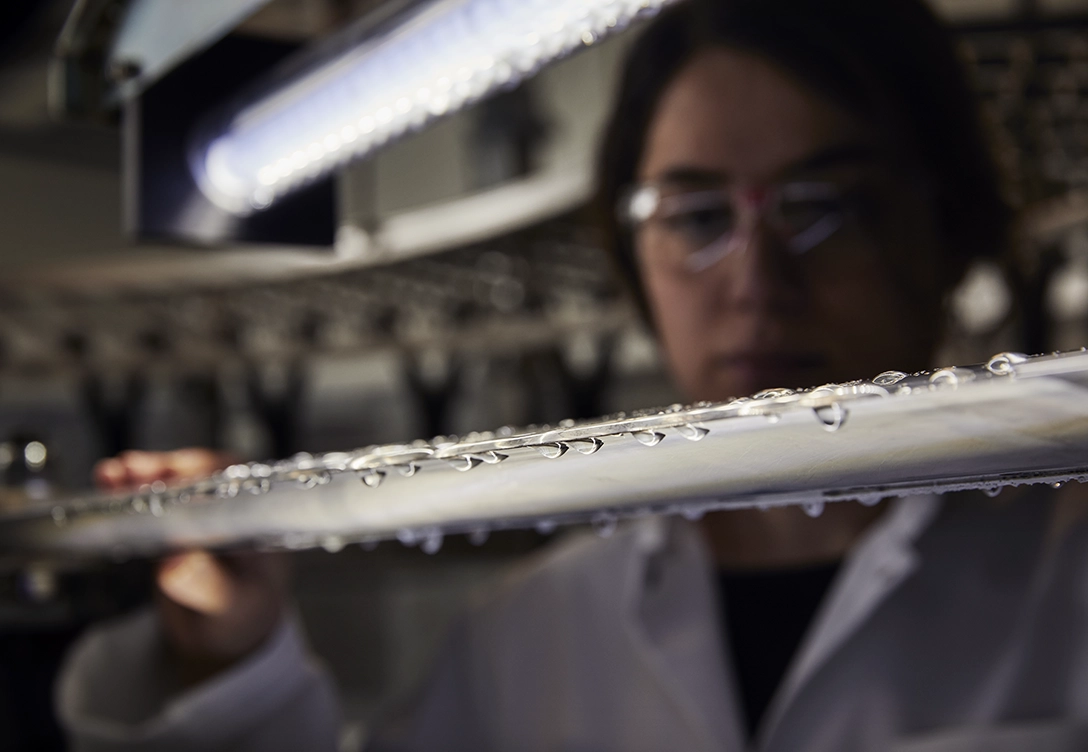

Benefit from our in-house Rain Erosion Test facility

Since 2019, we have our own in-house DNV GL RP-0171 compliant Rain Erosion Test facility., and we have put Hempablade Edge into several and exhaustive test sessions and assessments. This not only ensured the optimisation of its development and the LEP validation process, but it also means you can be sure it is proven to protect against rain erosion in the toughest conditions.

These rigorous tests culminated in a product that extends the intervals between scheduled maintenance, resulting in more turbine uptime and reduced operational costs.

Application video

Hempablade Edge application guideline

Watch our simple step-by-step guide on easy application with Hempablade Edge - a fast-curing top-layer designed to provide best-in-class erosion protection of the leading edge on wind turbine blades. Possibly the easiest application process for any LEP system available.

How we make a difference for our customers

The demonstration of Hempablade Edge 171 was impressive. Its durability, ease of application, and immediate protective results were remarkable. With Hempel’s expert support, we look forward to integrating it into our maintenance cycles and sharing its benefits across the wind industry.Maintenance and Technical members, All Works At Height Team, Belgium