Get more blades painted in one shift

As it is expected that the offshore MW installation capacity of wind turbines will increase from 12% in 2022 to 27% in 2028*, and with blades that keep getting bigger, blade and leading edge protection becomes crucial for making wind turbine investments profitable.

*Source: Orr & Boss | Wood Mackenzie.

Increase blade performance with Power of Less

The Hempablade range of coatings is a best-in-class full system solution for blades and LEP that delivers better protection and performance with less material, waste and work.

Straightforward, efficient application

The 2-step top coat eliminates the need for a third operator reducing the manpower cost of 30%.

Boost turbine performance

The coating is applied in a thin layer and is well-tapered to the blade surface, while its low DFT properties reduce the impact on the blade’s AEP performance.

The sustainable choice

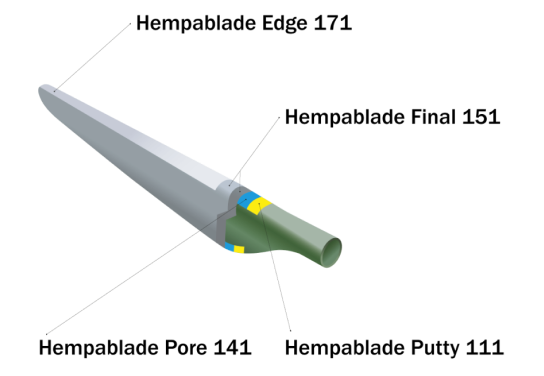

The Hempablade coating system

-

Hempablade Putty 111A fast-curing, solvent-free and light-weight 2-component polyurethane putty that can be used to form edge profiles and fill defects on the surface of the wind turbine’s blade prior to finishing coatings or LEP. It offers a combination of a good mechanical properties, easy application and high-build capabilities.

-

Hempablade Pore 141A fast-curing, solvent-free, polyaspartic-based porefiller with excellent self properties that can be used to fill pinholes in substrates.

-

Hempablade Final 151A high performance, fast-curing, two-component waterborne polyurethane topcoat for wind turbine blades.

-

Hempablade Edge 171A fast-curing top-layer designed to provide best-in-class erosion protection of the leading edge on wind turbine blades. Possibly the easiest application process for any LEP system available.

Power of Less

Benefit from our in-house Rain Erosion Test facility

These rigorous tests culminated in a product that extends the intervals between scheduled maintenance, resulting in more turbine uptime and reduced operational costs.

Strengthen your wind blades projects with Hempel expertise

Our ‘Power of Less’ philosophy means you get more than just advanced coatings - you access a partnership that offers dedicated support, proven solutions, and a commitment to reducing environmental impact.