Why durability classification is essential to selecting the correct passive fire protection coating system for your project

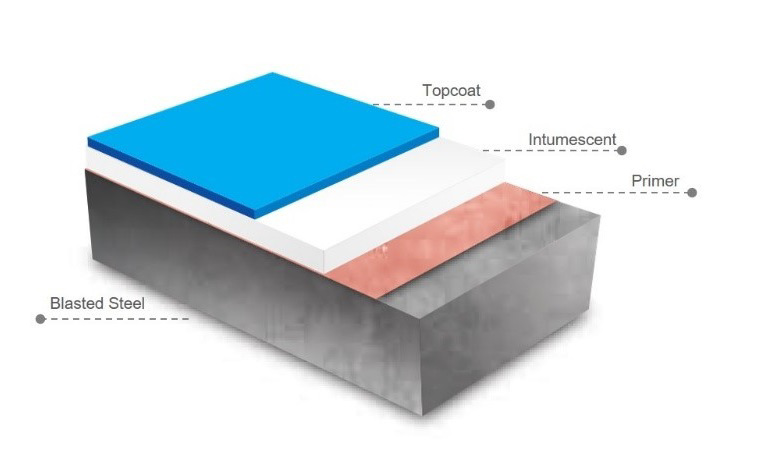

Intumescent coatings are reactive coatings used to minimise the effects of a fire. Applied to structural steel, they swell to form a layer of inorganic carbonaceous char when exposed to temperatures above 250ºC. This insulates the steel from the heat, enabling it to maintain its load-bearing capacity for longer. As a result, there is more time for evacuation of the building and emergency response, potentially saving lives.

There are a number of factors to consider when specifying intumescent coating systems, including both fire duration and durability, to ensure that the system is fit for purpose in the event of a fire.

Two key specification considerations

When intumescent coating systems are specified, ‘fire duration’ (i.e. the amount of time that the system will enable the steel to maintain its load-bearing capacity during a fire) is often the key consideration. Typically, fire duration ranges from 30 minutes to 120 minutes. The fire duration required for a specific building depends on a number of factors and is often set by local building codes.

However, another key consideration – durability – cannot be overlooked. Durability is the ability of the reactive coating system to maintain an adequate level of fire protection after exposure to environmental conditions, either during the construction phase or during end-use. It is very important that durability is predicted correctly, as premature weathering or aging of the coating system may have a negative effect on the intumescent coating’s fire protection properties.

Both fire duration and durability should be taken into account when specifying the full system.Durability during construction and in-service

The durability of an intumescent coating system may be affected by both the construction environment and the end-use environment. For example, an intumescent coating system specified for low humidity interior end-use conditions may be exposed to adverse exterior conditions during the transport and construction phase. In this case, a sealing topcoat may be needed to protect the intumescent coating, even though it is not required for the end-use conditions.

Therefore, when making a specification, it is very important to know what conditions the coating system will be exposed to during application, transportation and construction, as well as the end-use in-service conditions.

What affects system durability?

During its lifetime, an

intumescent coating system may be subject to a variety of environmental

conditions that affect its performance. The durability of the coating system

depends on its ability to withstand these conditions, specifically the adverse

effect of weathering and corrosion provoked by water, humidity, pollution,

temperature changes and UV light.

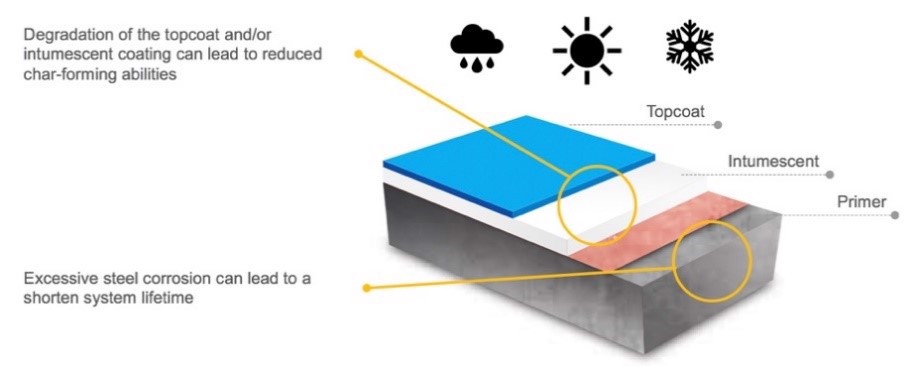

Figure 2. Effect of weathering on intumescent systems.

-

Corrosion of the substrateAs with most coating systems, atmospheric weathering conditions can cause corrosion at the interface between the primer and the substrate, which may shorten the lifetime of the coating system

-

Humidity and intumescent performanceDue to their reactive nature, intumescent coatings are rather sensitive to water and humidity. Over-exposure to humidity can affect the coating’s char-forming properties, resulting in a shorter fire duration. Therefore, a topcoat is often specified to act as a sealer coat and prevent moisture reaching the intumescent coating.

The topcoat must be able to withstand exposure to atmospheric elements, such as UV light, temperature variations and rain. Also, in fire scenario, it must allow the intumescent coating to react and must not prohibit expansion. Therefore, all topcoats must be tested in fire conditions prior to approval.

Durability classification: Testing and approval of intumescent systems

Like other protective coating systems, intumescent coating systems are tested and approved according to ISO 12944 ‘Corrosion protection of steel structures by protective coating systems’, which specifies test methods and conditions for assessing the degree of resistance to corrosion in different environments. ISO 12944 (part 2) classifies corrosive environments from C1 (very low corrosive environments) to CX (extreme corrosive environments).

|

Exposure types according to EAD350402-00-1106 Reactive coatings for fire protection of steel elements |

||

|

Type X |

Exterior |

All climatic conditions |

|

Type Y |

Internal and semi-exposed |

Temperatures below 0ºC but no exposure to rain and limited or causal exposure to UV |

|

Type Z1 |

Internal with high humidity |

Humidity equal to or higher than 85%, excluding temperatures below 0ºC |

|

Type Z2 |

Internal |

Humidity lower than 85%, excluding temperatures below 0ºC |

In addition, as durability is a key parameter, specific testing of intumescent coating systems is performed after the coating system has been exposed to standardised humidity/UV and temperature conditions. In order to obtain a CE marking, intumescent coatings must be tested and approved according to EAD350402-00-1106, which covers reactive coatings for fire protection of steel elements. The EAD (European Assessment Document, issued by www.eota.eu) specifies test methods and conditions for assessing the coating system’s ability to maintain its fire duration across its entire specified lifetime when exposed to a corrosive environment. EAD350402-00-1106 (previously ETAG018 part 2) classifies exposure environments from Type Z2 (low humidity internal environments) to Type X (exposed exterior environments).

As with ISO 12944 (part 6), the EAD specifies accelerated tests to establish performance. However, it is recommended to perform both accelerated and natural weathering tests during system development. All accelerated tests are performed in comparison with unweathered reference panels. Following the prescribed exposure, the fire duration of both the weathered and unweathered panels are compared.

Durability classification: Equivalency of ISO and EAD

The two testing systems (ISO 12944 and EAD350402-00-1106) are not direct equivalents. ISO12944 relates to corrosion environments and EAD350402-00-1106 relates to specified durability environments. However, when used together they give a good indication of the combined anti-corrosion and fire protection performance of a given coating system in different construction and end-use environments.

|

Classifying environments. The environmental categorisation systems for corrosive and fire protection coating systems British Coatings Federation, Ref. G020 version 2 , September 2017 |

||

|

Exposure Description |

Typical examples of locations similar to ISO 12944 |

|

|

Type X |

Exterior |

Similar to C3 external and C4 environments |

|

Type Y |

Internal and semi-exposed |

Similar to C2 external and C3 internal environments |

|

Type Z1 |

Internal with high humidity |

Similar to C2 internal |

|

Type Z2 |

Internal |

Similar to C1 environments |

The table on the left, from the British Coatings Federation, provides a rough equivalence between the two standards.

The ISO 12944 performance testing (part 6) aims to determine the anti-corrosion performance of a coating system by exposure to various test regimes, such as water immersion, water condensation, neutral salt spray and cyclic aging. This testing does not differentiate between interior and exterior. The basic pass/fail criteria are steel corrosion and film defects, such as blisters or cracks.

Crucially, the EAD350402-00-1106 performance testing also determines if the fire performance of an intumescent coating system is maintained after exposure to various test conditions, such as cycles of UV, humidity and temperature. In this case, the various conditions correspond to exterior, interior or semi-exposed environments.

Whilst a coating tested and confirmed to meet a certain EAD350402-00-1106 category cannot be said to meet an equivalent C1-C4 category from ISO 12944 (part 6), the industry table above suggests a rough equivalence. Some intumescent products, such as epoxy-based or hybrid intumescents, can be exposed to corrosion environments higher than C4.

Typical system lifetime

Combined, the ISO12944 and EAD350402-00-1106 standards demonstrate an intumescent system’s performance in different environments. With the correct specification, application and maintenance, an intumescent system should have a minimum lifetime in external environments (Type X) of 10 years. During that time, the system will deliver the correct level of corrosion protection and, if required, fire protection. Many intumescent coating systems may last for longer.

For internal systems, as long as the topcoat is not exposed to external conditions for an extended period of time (up to 1 year for some systems), the lifetime of the system should match that of the building.