Decision making supported by data

Get a clearer view of how you can improve your vessel’s performance

Plan your dry dock to ensure that the 40% of your vessel below the waterline continues to contribute to performance throughout the next five years – helping you reduce costs, meet regulatory demands, support sustainability goals and stay commercially flexible.

Hempel’s vessel-specific assessment supports a data-driven evaluation of multiple dry-dock and coating strategies. By understanding the implications of each scenario, you can optimise decision-making for long-term performance – with lasting returns, not just a new layer of paint.

A proven framework for performance enhancement

How our vessel-specific assessment guides your dry-dock planning

Our vessel-specific assessment combines advanced, data-driven modelling with practical experience from over 5,000 real-world hull coating applications.

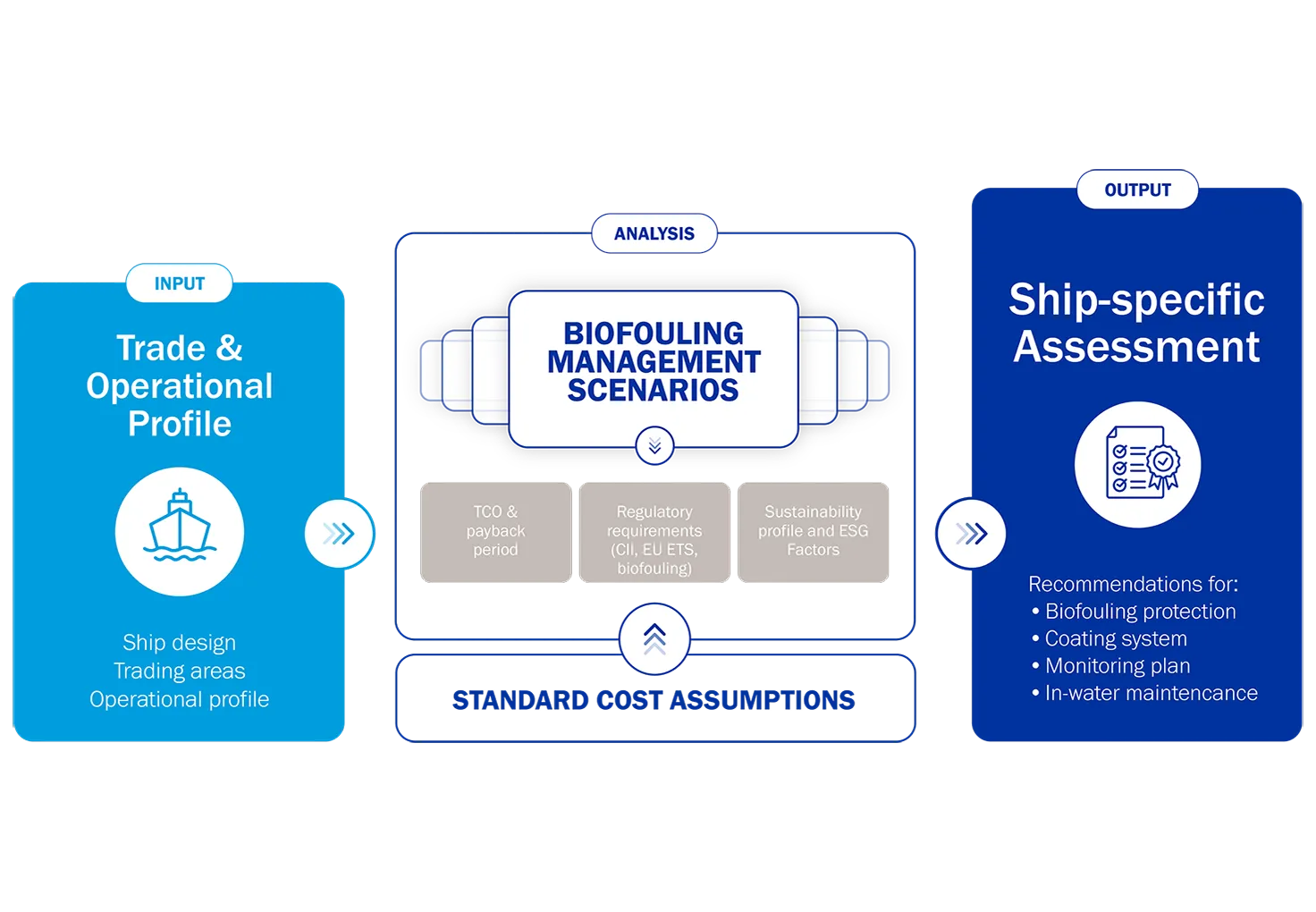

Working closely with you, our Hull Performance Solutions Managers model different dry-dock and coating scenarios to show the impact of each choice – including total cost of ownership, payback period, impact on regulatory requirements such as CII, EU ETS and biofouling rules, as well as key sustainability drivers.

The result is a biofouling management scenario tailored to your operational goals – with clear recommendations on coating selection, biofouling protection, monitoring plans and in-water maintenance.

A science-based foundation

The scientific background for our vessel-specific assessment

Our vessel-specific assessment is based on a robust framework developed by Hempel’s maritime and coating experts. It combines advanced scientific modelling with real-world operational insights to deliver tailored performance recommendations.

The framework is outlined in detail in our whitepaper Navigating energy efficiency dilemmas in a decarbonisation era – which demonstrates how it can be used as a decision-making tool for selecting the best energy efficiency measures for your vessels.

Complete your performance enhancing initiatives

More support for dry docking planning – and beyond

Planning and beyond

More coating options

Our advisors use the digital Coating Selector to match your strategy with the right coating combination for each hull section. With conventional antifoulings and the industry’s widest silicone range, we ensure long-term vessel protection.

Planning and beyond

More flexibility

With FlexSystem, you can paint in the rain, pause and restart, and apply from 0°C to 40°C – making it easier to avoid unexpected delays and improve robustness of your silicone coating.

Planning and beyond

More lasting performance

Our SHAPE system provides ongoing performance monitoring – giving you early warnings, actionable insights and clear guidance to avoid fouling risk and stay compliant between dockings.

Discover the benefits of a hull coating upgrade

Dry dock planning support for any vessel type

Impact of a hull coating upgrade

Bulk carriers

Get our bulker-specific total cost analysis to see how a premium hull coating will improve the performance of your bulkers.

Impact of a hull coating upgrade

Container carriers

Get our container-specific total cost analysis to see how a premium hull coating will improve the performance of your containers.

Impact of a hull coating upgrade

Tankers

Get our tanker-specific total cost analysis to see how a premium hull coating will improve the performance of your tankers.

Impact of a hull coating upgrade

LNG carriers

Get our gas carrier-specific total cost analysis to see how a premium hull coating will improve the performance of your gas carriers.

Impact of a hull coating upgrade

Cruisers

Get our cruiser-specific total cost analysis to see how a premium hull coating will improve the performance of your cruisers.

Impact of a hull coating upgrade

Dry dock coming up

Want a tailormade analysis for a specific vessel? Get a vessel-specific report on total costs, payback period, and impact on CII, EU ETS and Vref.