Elevating Power Plant protection with Avantguard® 860

Costing some €1.39 billion, the Ptolemais V expansion is Greece’s largest investment in energy production. Set to produce 660MW of power, it will produce affordable electricity for the people of Greece with significant benefits to the Greek economy and environmental footprint.

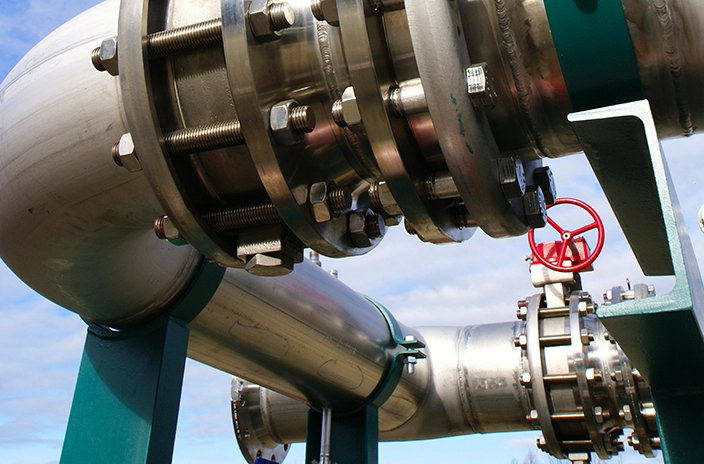

Hempel are pleased to have been trusted to provide superior performance1 protective coatings for steel structures for this project, including the boiler house.

Originally specified with inorganic zinc silicate primer, we proposed a change to our advanced Hempadur Avantguard 860 primer, since it provides many benefits including best-in-class productivity2 with

reduced over-coating times.

Unlike traditional zinc epoxies, Avantguard technology activates all of the zinc in the coating, which significantly improves the coating’s anti-corrosive performance and mechanical strength, while remaining easy to apply. This means more accurate application, in a shorter time with the assurance of a high performing, longer lasting coating and lower future maintenance costs.

Avantguard 860 delivers the corrosion protection at the level of an inorganic zinc silicate with the application benefits of an epoxy.

The challenge

The solution

Major new power plant switches to Avantguard® 860 for improved productivity and superior protection

With best-in-class drying times2, 4x faster than inorganic zinc silicates, and proven superior1 performance, our Hempadur Avantguard 860 primer was the answer.

Based on our recognised activated zinc technology, Hempadur Avantguard 860 sets a new standard in the protective coatings industry.

The additional benefits afforded by using Hempadur Avantguard 860 were supported by tests proving our product provides the same level of corrosion protection as the originally specified inorganic zinc silicate, whilst also considerably minimising the application risks and improving the over coating interval time. Due to this, the green light was given to proceed with the project using Hempadur Avantguard 860.

As a result, the project will benefit from an improved application process and a robust coating solution that will keep the power plant in pristine condition for years to come.

1 This superiority has been independently proven by third party laboratory neutral salt spray tests according to ISO 9227. In this test, steel protected with Avantguard produced a lower evolution of rust creep, assessed according to ISO 12944-6, when tested up to 3x the duration for C5-high environments.

2 Hempadur Avantguard 860 is 4x faster drying than standard IOZs, based on a typical system, when comparing product data sheets.

At a glance

- Coating system: Hempadur Avantguard 860, Hempadur Mastic 4588W, Hempathane Topcoat 55210

- Customer: Terna S.A., Greece

- Total project value: 265,000 litres

- Application: Airless spray

Dive deeper

Featured product brands

Our Cases

How we’ve helped our customers

Verwater achieves rapid tank transformation without downtime

Leveraging Hempel’s expert support and Defend 630 lining system, Verwater completes tank building project for downstream client in Denmark

Advanced corrosion protection for sour crude oil tanks

High performing Hempaline system effectively combats corrosion in sour crude oil tanks, earning customer’s trust for future projects.

Hempel solution trusted for valve coating

Hempel’s CUI and high heat solution is specified to provide corrosion protection across various temperature categories.