Staying profitable in a challenging market

Focusing on blades is central to meeting the challenge as many older wind turbines have inadequate blade protection, and damaged or eroded blades cause poor aerodynamics. It is estimated that leading edge maintenance contributes to more than 50% of blade maintenance costs*. LEP protection is therefore key to increasing your AEP while ensuring benefits from longer service intervals and lower servicing costs.

*Source: Wood Mackenzie.

Let Power of Less boost your maintenance activities

The Hempablade range of coatings is a best-in-class LEP protection that delivers better protection and performance with less material and waste and shorter application and repair times.

Outstanding LEP protection

Strong performance, higher service intervals

The coating is applied in a thin layer to the blade surface, and its superior protection performance at the lowest DFT thickness in the industry impact on the blade’s AEP performance.

Straightforward, fast application

This lowers paint consumption, reduces application time and cuts drying time, so you can coat more blades in each shift. And, with simple application with brush or roller, you get a high-quality finish – fast.

Hempablade Edge 171

Power of Less

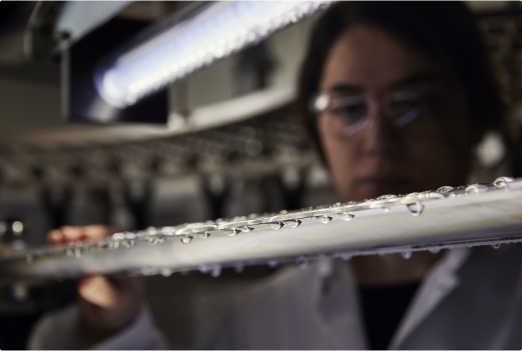

Benefit from our in-house Rain Erosion Test facility

At Hempel, we have our own in-house DNV GL RP-0171 compliant RET facility. And we’ve put Hempablade Edge 171 to the test in more than 600 exhaustive test sessions and assessments. This not only ensured the optimisation of its development and the LEP validation process, but it also means you can be sure it is proven to protect against rain erosion in the toughest conditions.

These rigorous tests culminated in a product that extends the intervals between scheduled maintenance, resulting in more turbine uptime and reduced operational costs.

Application video

Hempablade Edge 171 application guideline

Strengthen your wind blades projects with Hempel expertise

Our ‘Power of Less’ philosophy means you get more than just advanced coatings - you access a partnership that offers dedicated support, proven solutions, and a commitment to reducing environmental impact.

Webinar

Maximising Performance: Leading Edge Protection on wind turbine blades