Hempaguard X7 application to the Superyacht Missy

Superyacht Missy was painted in March 2021 in Palma de Majorca with the original paint system on the underwater hull applied during the new building of the vessel in 2016 and re-touched up at least twice afterwards.

To secure the optimal product performance, Hempel Yacht coating advisors suggested to remove the existing coating and apply the complete Hempaguard X7 underwater system on the underwater hull of the Superyacht.

The challenge

The solution

Full coatings and service package for the vessel created by Hempel team

All surface preparation and paint application during this project were carried out inside a tent sheltered from the outdoors conditions. Air extraction was implemented during and after paint application.

An initial condition assessment of the underwater hull coatings was carried out in preparation for recoating with a Hempaguard X7 fouling defence system.

The boat was docked several weeks before and an initial high pressure fresh water washing was carried out shortly after lifting.

Minor spot repairs of scattered damages and scratches of the existing grey silicone were carried out mostly by sanding of the exposed undercoats.

Major spot repairs by abrasive blasting were carried out on the keel areas where more extensive mechanical damages had been observed and one touch up coat of Hempel's Light primer were applied on the previous day. These touch up repairs needed a second touch up of the same primer and a re-build with an epoxy filler before proceeding with the subsequent specified coats.

Upon arrival of the Hempel coating advisor, it was recommended to carry out a complete thorough high pressure wash of the complete underwater hull in order to remove dust and other contaminants from the silicone surface, this was done with a low power pump at 150 Bar.

Upon completion of the wash, an inspection of the existing silicone coatings was carried out and it was observed that all touch ups of lighter grey silicone paints were showing fair to low adhesion with the original silicone system.

Therefore the existing silicone system was completely removed from the hull and all appendages by mechanical means and abrasive blasting.

The first specified primer coat was applied by airless spray.

Masking along the water line was re-built to secure protection of the above water line areas.

The floor was wetted in order to minimize possible dust lifting inside the tented area. There were pending repair to be done on the keel, for this reason, this specific area was masked with plastic and was be painted on a later stage together with the support block spots.

The second specified coat, silicone tie coat, was applied by airless spray. Both wet film thickness and consumption were monitored during the application and were found according to the specified.

The final silicone topcoat was applied by airless spray. Once again, wet film thickness and consumption were monitored throughout the application and were found according to the specified.

It was also recommended to fresh water wash the underwater hull areas before undocking of the vessel in order to eliminate all possible contamination of the silicone coatings which could reduce the performance of the fouling defence system.

At a glance

- Vessel name: Missy

- Customer: CASA JULIA, S.A

- Location: Palma de Majorca

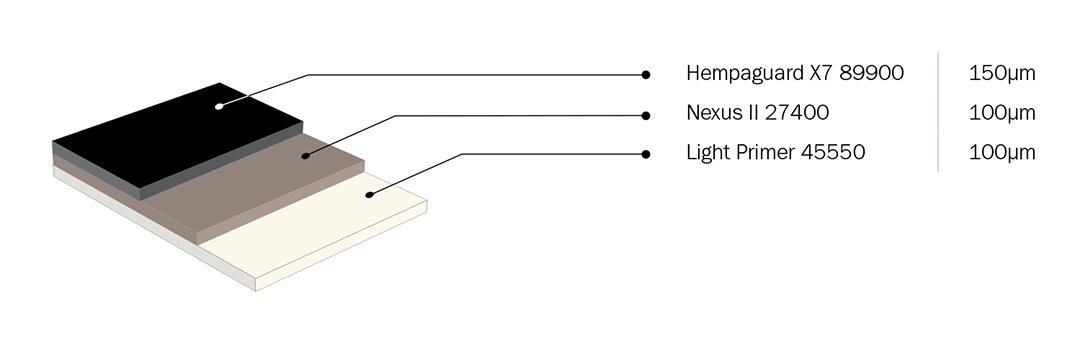

- Coating system: Hempel’s Light Primer, Hempel’s Nexus II, Hempaguard X7

- Date of application: March 2021

- Vessel area (area of use): Underwater area

- Application: Roller and airless spray

Our Cases

How we’ve helped our customers

Hempaguard proves to be the most effective solution for Missy 33

Full coatings and service package for the Superyacht provided by Hempel team

Hempasil PRO application to the XP-44 Yacht

Hempasil Pro 87850 + Nexus II – the next evolution in the fouling release systems

G2 benefit from full coating and service solution

Hempaguard X7, with patented ActiGuard® technology, keeps G2 Superyacht effective worldwide, even during idle periods.