Transforming refinery insulation: Hempatherm IC system triumphs over CUI in a large Gulf Coast facility

traditional insulation for their Pentane spheres as part of an annual

turnaround exercise. Due to a tight maintenance schedule and high

Corrosion Under Insulation (CUI) problems, the client was in search of

an alternative solution that would return assets back to service quickly,

with less CUI risk, and improved insulation performance.

To meet these requirements, Hempel proposed the application of

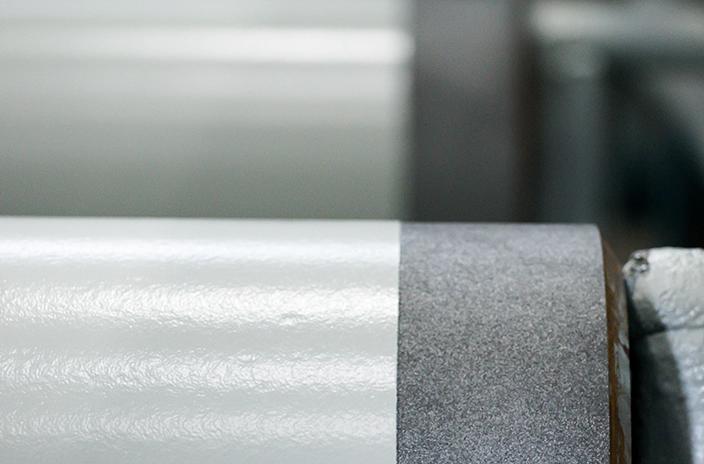

Hempatherm IC 175 and Hempatherm IC 170. These high-quality

insulation coatings replace traditional insulation and promote

sustained thermal performance over the service life of the asset.

At the end of the project, the refinery achieved optimal thermal

performance on the Pentane spheres while significantly reducing

application time, and the risks of CUI. The Pentane spheres now boast

enhanced longevity and reduced maintenance needs, which further

results in lower operational costs for the customer.

The challenge

Note 1: Customer wishes to remain anonymous

The solution

Enhancing thermal performanceand preventing long-term CUI risks

Hempatherm IC 175 and Hempatherm IC 170 were recommended as the ideal solution to the refinery’s CUI challenges. When used as a system, these high-performance coatings boast exceptional hydrophobicity and film build, creating an impenetrable barrier against water, safeguarding insulation and preventing CUI over the service life of an asset – estimated at 20 to 25 years.

Tailored to the refinery’s specific needs through thermal modelling, the system combined 32mm of Hempatherm IC 175 (made with aerogel technology), with 5mm of Hempatherm IC 170, to deliver optimal thermal insulation. The system performed better compared to conventional methods, slashing application time by over 40% (7 weeks vs. 12 weeks), while minimising downtime and costs.

At a glance

- Customer: Gulf Coast refinery

- Project: Insulation coatings on Pentane spheres

- Year: 2021

- Asset reference: Pentane spheres

- Project size: 1,160 m2 (12,500 ft2)

- Application: Spray applied using low-pressure high-volume spray equipment

- CUI system: Hempatherm IC 175, Hempatherm IC 170

Our Cases

How we’ve helped our customers

Protecting pipework and process equipment from CUI

Versiline CUI 56990 protects insulated pipework at polysilicon plant to reduce CUI risks and associated costs

BPCL approves Hempaprime CUI 275 for superior CUI Protection

Hempaprime CUI 275 proves superior in safeguarding BPCL refinery assets against corrosion in thermal and insulated environments.

Long term protection and cost savings achieved during maintenance

Facility undergoes CUI maintenance without disruption to production schedule.