Weld seams

The overlooked friction in vessel efficiency

A vessel’s hull has around 5 kilometres of weld seams, and although the welds protrude by only 3-9 millimetres, their dragging effect on a vessel’s operation adds up to a substantial amount.

While shipowners and operators recognise the energy efficiency gains achieved through hull coatings, the substantial inefficiencies caused by weld seams have remained largely unaddressed, until now.

While shipowners and operators recognise the energy efficiency gains achieved through hull coatings, the substantial inefficiencies caused by weld seams have remained largely unaddressed, until now.

The seamless solution for improved hull efficiency

SeamFlow is a new developed system of coating, application tools and dedicated services.

In conjunction with Hempaguard, SeamFlow aims at reducing friction by smoothing vertical weld seams, resulting in a significant reduction of drag and consequently bunker consumption and carbon emissions.

SeamFlow is easily applied during routine drydocking and it does not require extending drydock time if planned well — hence a quick and simple way to cut costs, increase efficiency, and progress towards meeting EEXI and CII targets.

In conjunction with Hempaguard, SeamFlow aims at reducing friction by smoothing vertical weld seams, resulting in a significant reduction of drag and consequently bunker consumption and carbon emissions.

SeamFlow is easily applied during routine drydocking and it does not require extending drydock time if planned well — hence a quick and simple way to cut costs, increase efficiency, and progress towards meeting EEXI and CII targets.

Enhanced efficiency

SeamFlow joins forces with Hempaguard, creating a synergy that maximises your benefits. This partnership is the key to ensure your vessels operate at peak energy efficiency.

Reduced bunker consumption

By smoothing over rough welds with SeamFlow, it significantly lowers drag and consequently reduces bunker consumption.

*Reduction is dependent on quality of the welding seam and vessel characteristics

*Reduction is dependent on quality of the welding seam and vessel characteristics

Reduced carbon emission

In a 5-year period, SeamFlow can reduce carbon emissions by 12,000 tonnes, helping to achieve emission reduction targets.

How SeamFlow works

By smoothing the welding seams, friction can be significantly reduced.

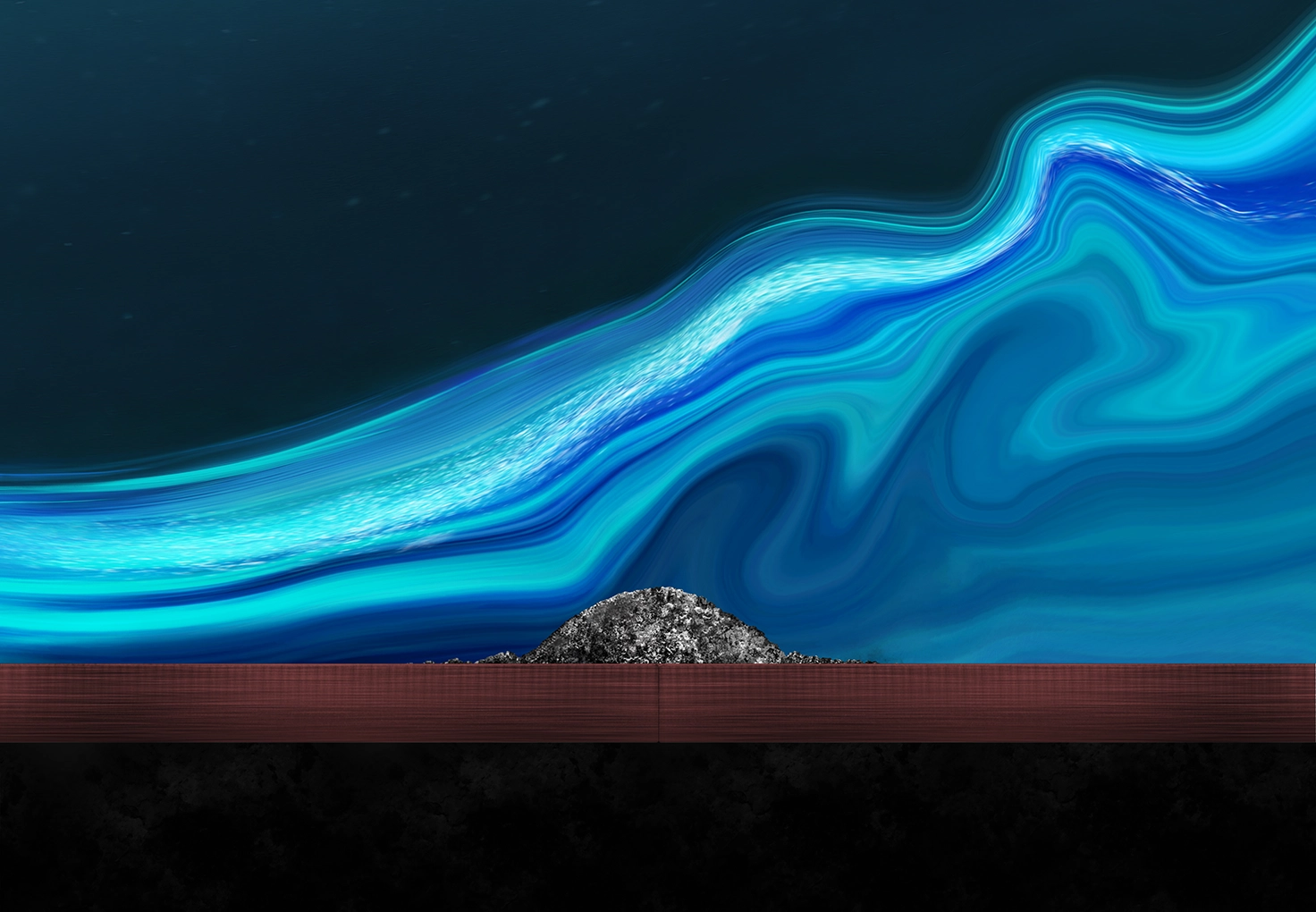

Before

Weld seams extend 3-9 mm from the hull, resulting in increased drag and higher fuel consumption.

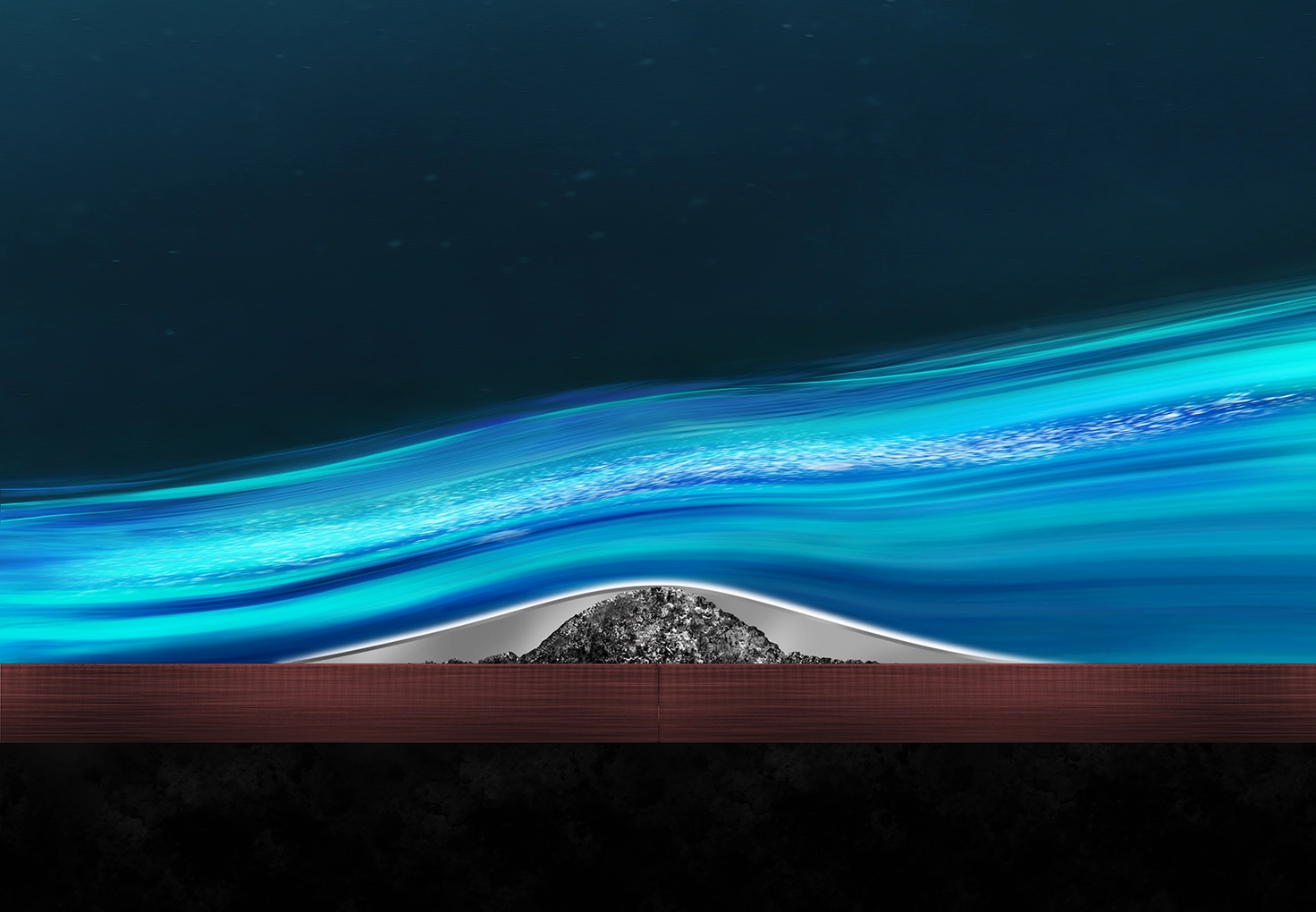

After

SeamFlow coats weld seams with a specially modified epoxy, reducing drag.

Pull the slider to see the effect of SeamFlow.

Innovative hull performance solutions

Applying a high-performance hull coating is one of the simplest and fastest ways to maintain a good CII rating and increase a vessel’s reference speed for EEXI.

By combining the industry leading Hempaguard hull coating with SeamFlow, you can maximise your benefits on bunker savings and energy efficiency of your vessels.

By combining the industry leading Hempaguard hull coating with SeamFlow, you can maximise your benefits on bunker savings and energy efficiency of your vessels.

-

Impact of SeamFlow on EEXI and CII

A part of Hempel Marine Services

SeamFlow is a new developed coating system applied during the routine drydocking by Hempel’s coating advisors who supervise and check for quality to ensure a high-quality coating finish that will last throughout the entire service life.