Revolutionise your corrosion protection

Our industry-changing patented Avantguard® technology with three activating components - zinc, hollow glass spheres and a proprietary activator:

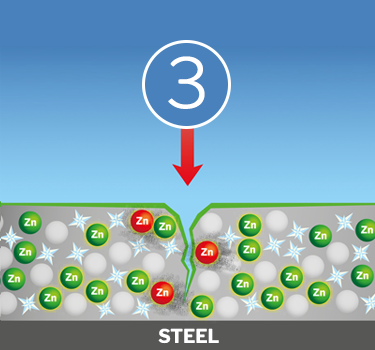

- Is the first zinc-rich primer to activate all 3 methods of corrosion protection: the Barrier effect, the Galvanic effect and the Inhibitor effect.

- Is the first zinc-rich primer to triple the activation of the zinc content, boosting the Galvanic effect beyond any standard in the market.

- Creates a much higher amount of insoluble salts than conventional zinc-rich primers, boosting the Barrier effect beyond any standard.

Avantguard® technology helps your coating system last up to 50% longer and protects your assets regardless of the environment they face.

Longer corrosion protection

Give your assets a longer life, even in the toughest conditions. Avantguard® is proven to deliver superior corrosion protection with extended durability, so your coating system lasts up to 50% longer.

Lower maintenance costs

Extended corrosion protection allows you to perform maintenance less often, reducing maintenance needs by up to 30% throughout the lifecycle of your asset. In addition, the special two-coat Avantguard® systems will instantly reduce your maintenance costs, through the reduced number of coats needed to complete the project.

Reduced application costs

Avantguard® is easy to apply and fast drying, even in high temperatures and humidity, so you’ll save up to 30% on the time needed to apply it. The unique patented technology with three activating components gives you the option to reduce the number of coats or coating thickness. Additionally, its self-healing capabilities also means your coating system will require less rework.

Take your corrosion protection to a higher level

Triple Activation with patented Avantguard® technology

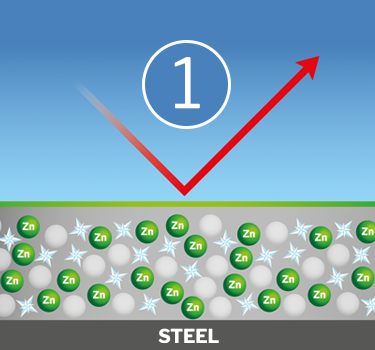

Barrier effect

Zinc salts formed throughout the film increase barrier properties to lower water permeability.

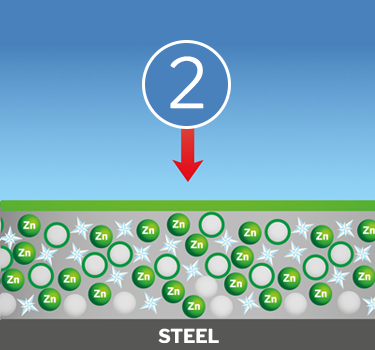

Inhibitor effect

Avantguard® captures the ions and creates a powerful inhibition effect to combat rust.

Galvanic effect

The unique activation process in Avantguard® efficiently utilises all the zinc content, extending the galvanic protection.

Dive in deeper

Learn more about how you can benefit from Avantguard®.

Get access to our webinars and whitepapers.

Webinars

Redefining anti-corrosion protection

Get an introduction to the Avantguard® product range and a deeper understanding of how our unique patented technology works.

Offshore maintenance challenges

Looking for a durable water repellent coating? Learn how our two-coat system shows a significant improvement on the anticorrosive properties compared to a standard coating material.

Whitepapers

How to make your industrial assets last longer in extreme conditions

Maintaining your assets doesn’t have to be that costly. Tests show that Avantguard® outperforms conventional zinc epoxies in the protection of steel against corrosion. Find out why and how you can benefit from it.

How to reduce your costs in the wind energy industry

Avantguard® not only offers increased durability, but also up to four times better coating intervals. Find out how Avantguard® overcomes the challenges of the wind energy industry.

How we've helped our customers

A switch for improved productivity

Avantguard 860 provides the same level of protection as an inorganic zinc silicate, whilst also improving over coating interval time.

Learn how Ptolemais V achieved improved productivity by making the switch.

A perfect match for decades

The major stationary blasting and coating company Brabant Groep is once again choosing our primers. Why? Competitive pricing and our fast-drying paint.

Learn why Brabant Groep trusts Avantguard®.

Paint scheme for severely corrosive environments

The enormous towers of Iberdrola’s Wikinger wind farm off the German coast demand optimal protection in CX Marine conditions.

Learn why Avantguard 770 is the natural choice for corrosion protection at sea.

Proven in laboratory testing and in real life

In third-party neutral salt spray tests, Avantguard® has consistently shown superior anti-corrosive performance compared to standard zinc-rich primers. Avantguard® has an extensive track record of successfully protecting assets across the globe.

How tough is your challenge?

Get superior protection no matter how corrosive your environment. Our Avantguard® products contain zinc levels of 65%-85%. Find the right product for your needs.

Avantguard 550

- A zinc epoxy primer

- Up to C5 high environments

Avantguard 750

- Versatile zinc-rich epoxy primer

- For all corrosive environments

Avantguard 770

- Zinc-rich epoxy primer

- For severely corrosive conditions

- Especially suited for maintenance

Avantguard 860

- Zinc-rich epoxy primer

- For the most corrosive environments

- A fast curing alternative to inorganic zinc silicates

Avantguard Selector

Welcome to Hempel's Avantguard Selector.

Discover the performance of Avantguard's Triple Activation technology against your key focus areas. Start by selecting from the three criterias:

- Select the environment's corrosivity in accordance with ISO 12944 standard

- Select the required durability of your coating system:

- Select your focus area