Future fact or future fiction?

Further harmonisation of the coating specifications of a significant number of oil and gas companies took a major step forward earlier this year with the publication of a new specification, S-715 Coating & Painting for Offshore, Marine Coastal & Subsea environments, issued by the International Association of Oil & Gas Producers (IOGP).

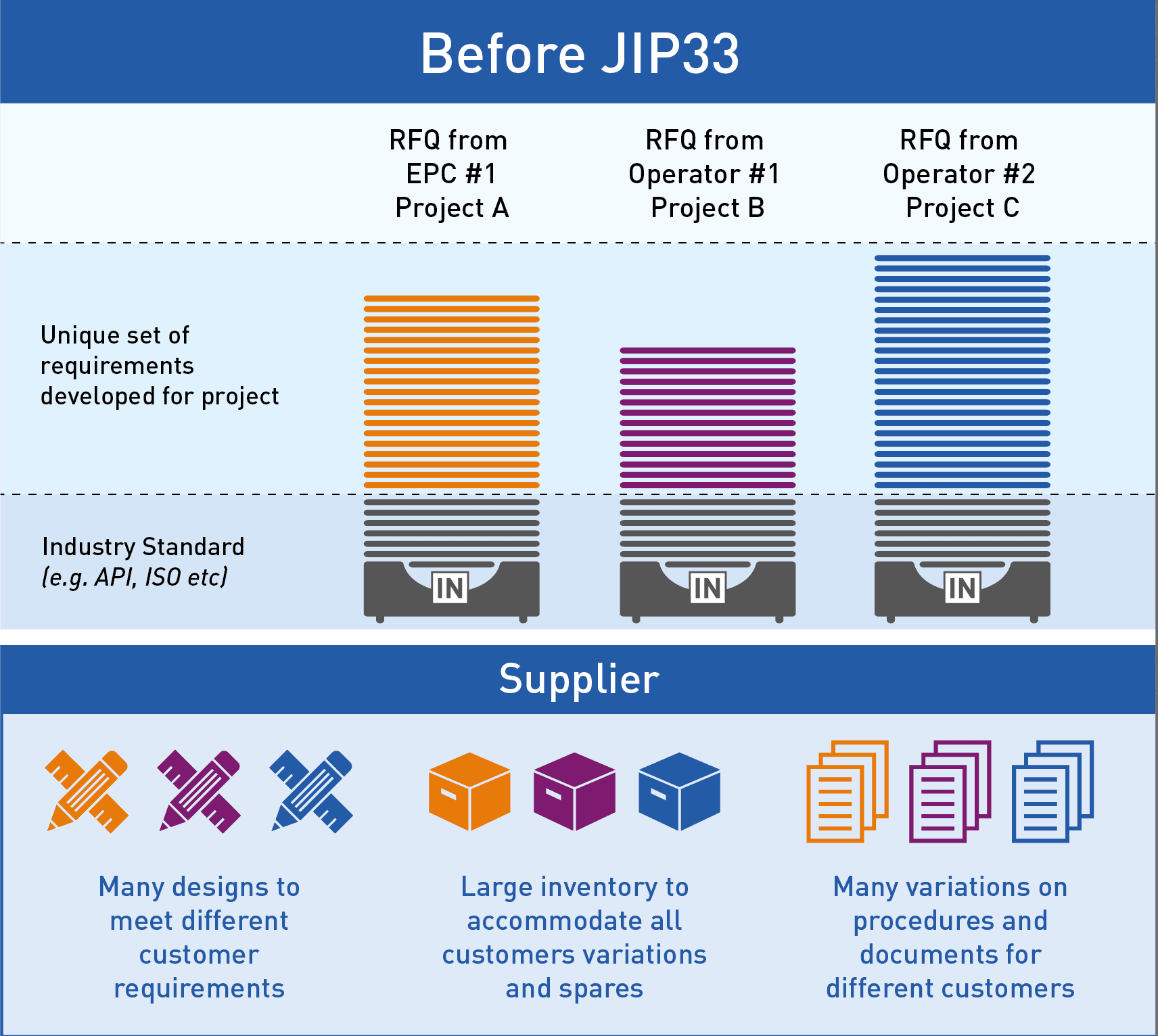

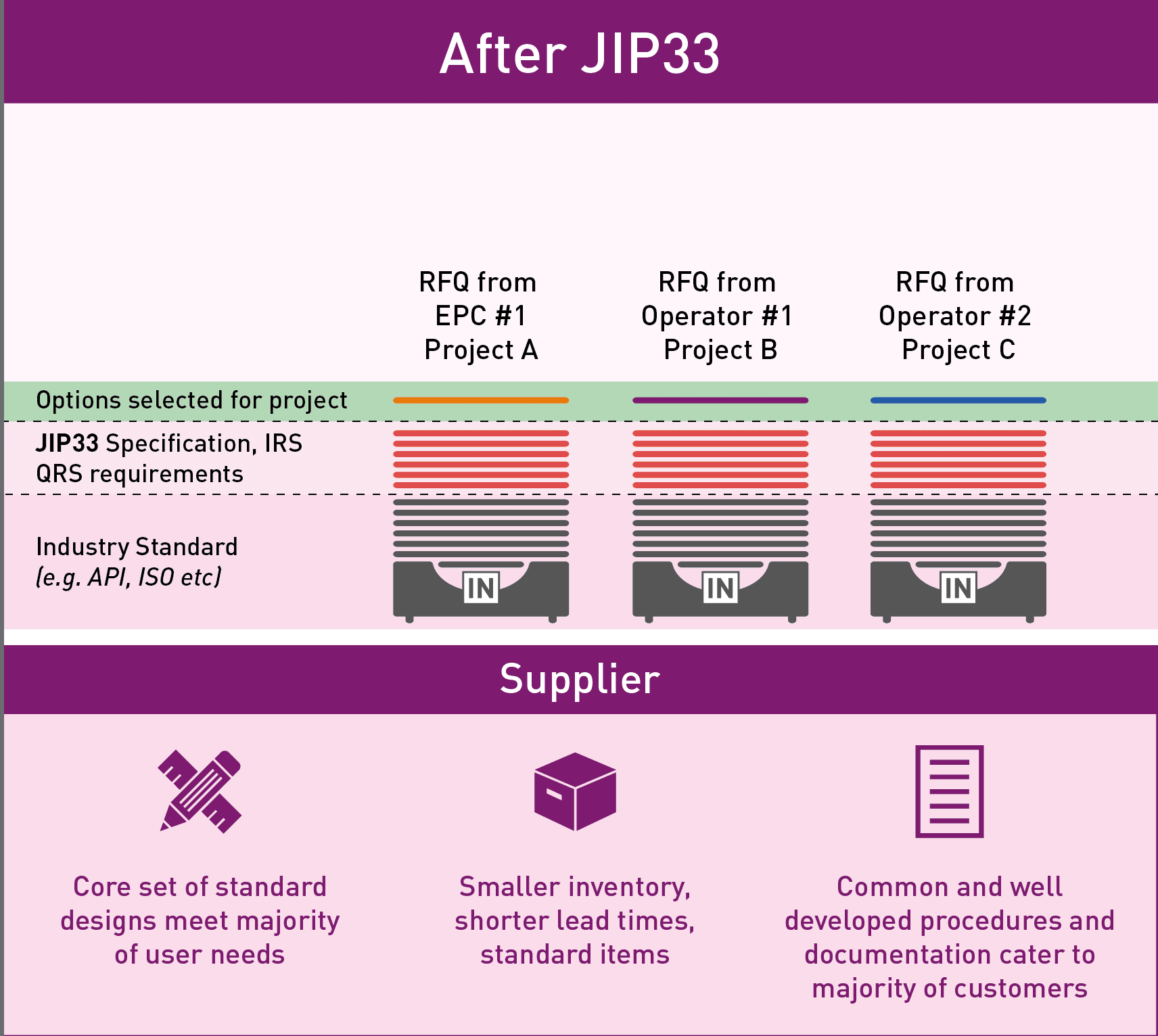

The document was an output from the Association’s Joint Industry Project 33: Standardising Procurement Specifications, the objective of which was to make a step-change improvement in the specification, procurement and delivery of equipment for the oil and gas industry through the use of standardised procurement specifications (see figure below).

The document was issued in July as part of the third phase of this joint industry programme, coatings were also featured in some of the earlier equipment specifications issued during Phases 1 and 2, but to a much lesser degree.

The specifications are freely available to download to anyone via the JIP 33 specification library [1].

S-715 in more detail

The specification follows a common format of the JIP 33 equipment specifications and consists of 4 individual documents.

Supplementary specification to NORSOK M-501

As the title suggests this specification draws heavily on the current Edition 6 of NORSOK M-501 which has been the benchmark standard for coatings in the offshore space for many years. In fact the main document exists as a supplementary “overlay” to the NORSOK standard referring to specific paragraphs in that document and adding, removing, or expanding upon the text within it.

Whilst NOROSK M-501 is often perceived as an offshore specification the scope of the new document is extended to include coastal onshore facilities.

There are some significant changes to the NOROSK document, including;

- extension of System 1 to cover higher temperature systems,

- the new standard does not address passive fire protection.

- removal of systems 8 and 9,

- inclusion of a new system 10 to cover inert multi-polymeric matrix type coating materials.

Coating systems are described in the form of an annex which details each coating system type as well as requirements for dry film thickness, number of coats, pre-qualification testing, and inspection requirements. Prequalification requirements have been added to a number of systems where previously these did not exist within the base NORSOK document.

Selection of the relevant coating system for each use area is also described in a tabular format.

As well as the supplementary specification, three other documents are also included.

Quality requirements specification (S-715Q)

Information Requirements (S-715L)

Data sheet (S-715D)

Summary

-

Reference

Article reprinted from Corrosion Management, vol 158, November/December 2020, with permission