Choosing the perfect coating for your cargo holds

Your cargo holds are subject to extremely harsh conditions. Loading and unloading dry cargo causes abrasion, impact and mechanical damage; while new high-speed loading techniques can cause ‘shooting’ damage to unprotected holds. In addition, certain cargos expose your cargo holds to high temperatures and harsh chemicals, which can damage and weaken the steel.

In these tough environments, you need a protective coating you can trust. By choosing our proven cargo hold coatings, you get a coating that’s strong enough to protect your hold against the most punishing dry cargos, and durable enough to ensure you get a long repair interval and reduced maintenance costs.

In these tough environments, you need a protective coating you can trust. By choosing our proven cargo hold coatings, you get a coating that’s strong enough to protect your hold against the most punishing dry cargos, and durable enough to ensure you get a long repair interval and reduced maintenance costs.

Find the right product for your needs

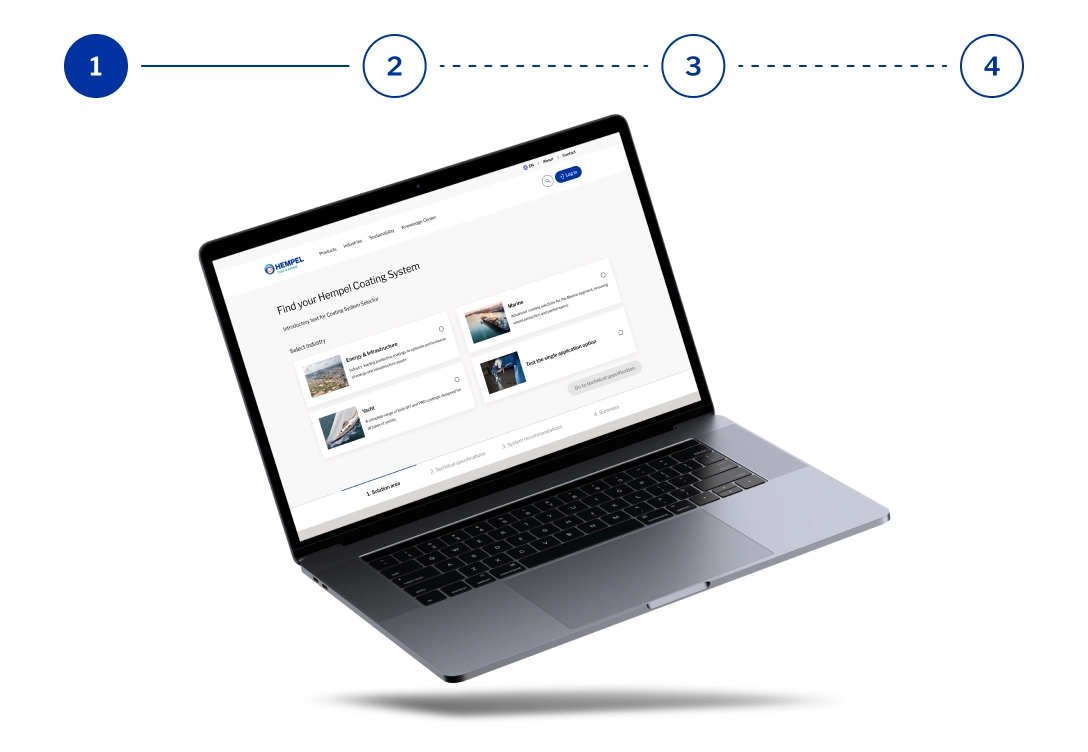

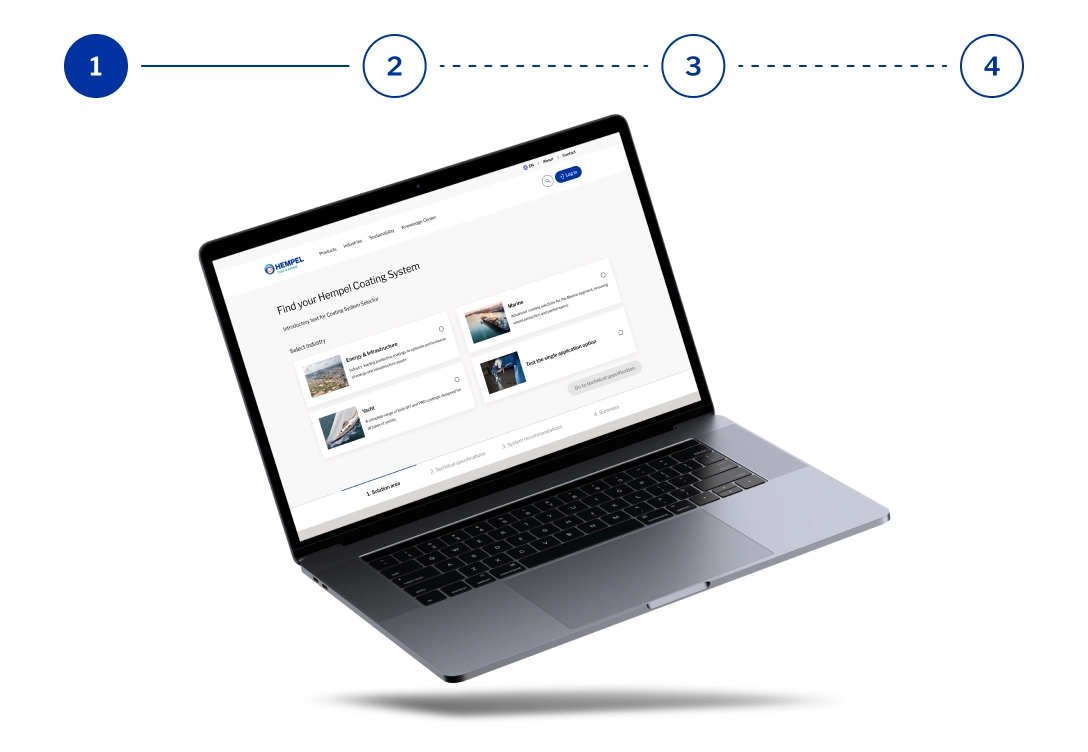

Coating system selector

Discover the perfect coating system for every situation